It’s an exciting day here at Realtime Robotics as we’ve officially rolled out our latest offering – Optimization-as-a-Service. Put simply, it is a sophisticated solution designed to enhance productivity in industrial robotic applications. The solution leverages our proprietary optimization software and deep robotics and application engineering expertise to revolutionize customers’ manufacturing processes, optimizing robot paths and interlocks to cut cycle times and improve efficiency. To top it all off, we can do this for them faster and easier than they can do themselves – and we can do it without disrupting their existing operations.

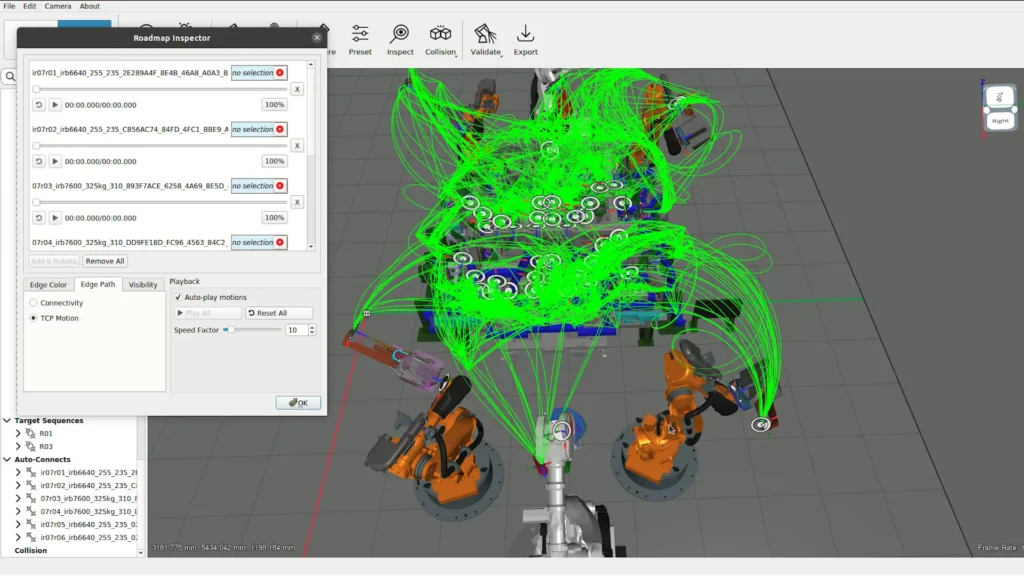

Key features of our optimization solution include the ability to rapidly generate and test hundreds of thousands of potential robot paths. This process, driven by proprietary algorithms, determines optimal motion sequences based on parameters such as target assignment and robot reach. Automatic interlocks enable robots to operate in closer proximity, further enhancing efficiency.

Already Generating Results

A recent deployment of Realtime Robotics’ Optimization-as-a-Service solution took place at Volkswagen Commercial Vehicles in Hanover, Germany. The goal was to enhance the cycle time in a 2-robot cell responsible for welding car doors for the ID. Buzz vehicle line. By analyzing the manufacturer’s digital twin, our optimization solution identified bottleneck areas and proposed optimizations, all without interrupting ongoing production. The outcome was a significant reduction in cycle time, providing tangible evidence of the service’s efficacy.

How It Works, Simplified

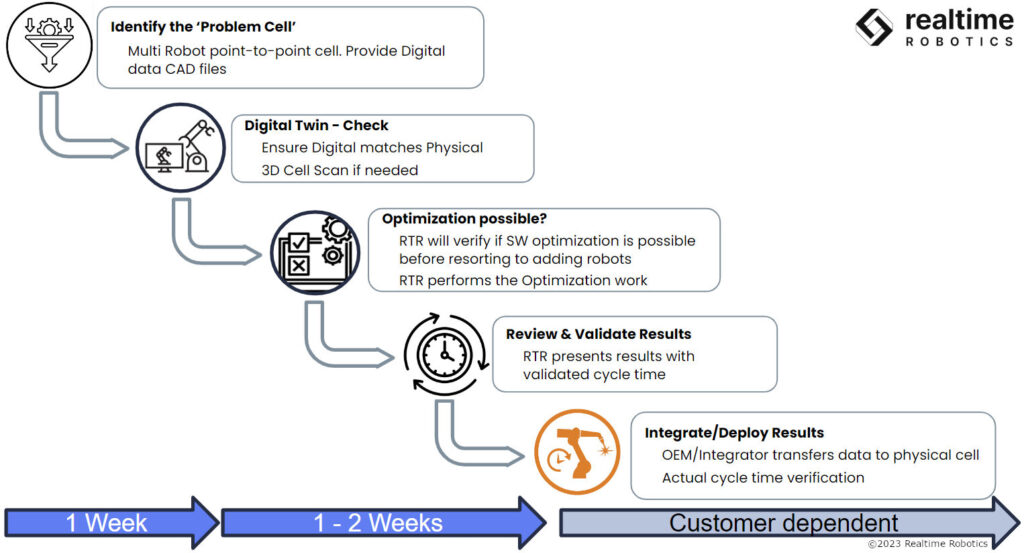

There are only four simple steps to utilize the service and shave precious seconds off of your cycle time:

- Provide us with your simulation CAD file for bottlenecked cells.

- Our engineers quickly review and determine if optimization is possible.

- If so, we employ proprietary algorithms to optimize the workcell in a matter of weeks, reducing cycle times through improved paths and sequences.

- Once validated, the results can be seamlessly transferred to a customer’s production floor – and they can sit back and watch their efficiency levels improve.

A Fast, Streamlined Process

Unlike traditional methods that may require years of programming experience and extended downtime, Realtime Robotics’ Optimization-as-a-Service offers a streamlined, risk-free process. The solution evaluates hundreds of thousands of possibilities for any robot brand, providing insights within days on potential cycle time savings. Implementation is swift, requiring only a single shutdown to deploy optimized paths and eliminate bottlenecks.

Our Optimization-as-a-Service offering delivers results when you cannot spend months squeezing more productivity out of your automation cells.

And when it comes down to it, who doesn’t want more bang for their manufacturing buck? This isn’t just about making robots move; it’s about making them dance to a more efficient and effective tune.

To learn more about how Optimization-as-a-Service can help your organization, click here.