Flexible

Embrace dynamic environments

RapidSense monitors and detects dynamic obstacles, so your robots can react and move around them—in real time. RapidSense, aided by 3D sensors, works on the fly, identifying changes and immediately guiding the robots to avoid collisions.

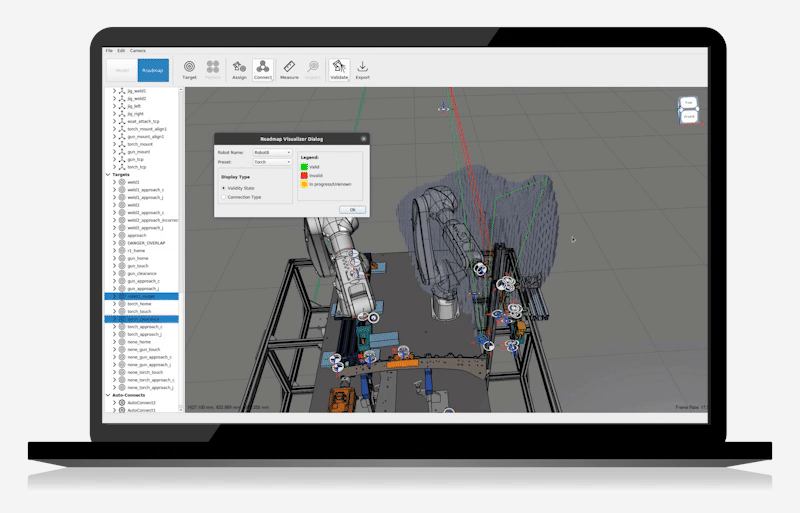

1. Calibrate sensors

The first step is to calibrate the sensors in RapidPlan to match robot coordinate frame. We provide details on how to handle setup and configuration for both intrinsic and extrinsic parameters. This step is key to ensure that camera placements reduce occlusions.

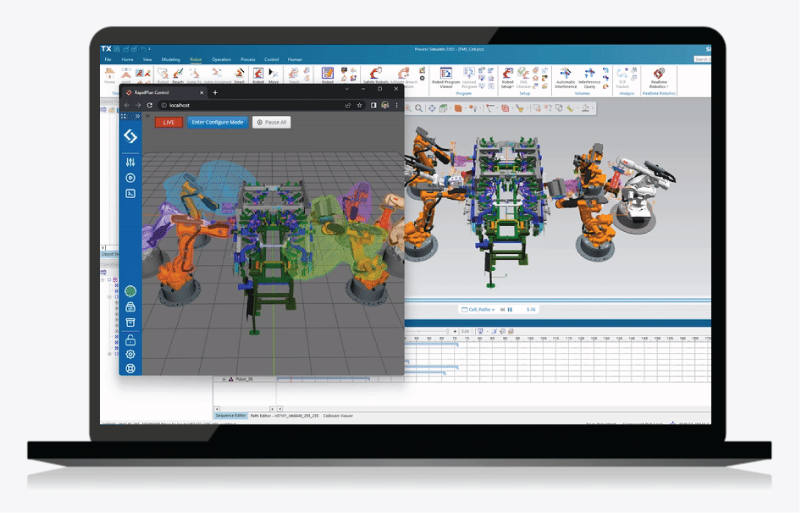

2. Configure the cell

The second step is to configure high-resolution volumes to monitor for changes. Whether it is a change in the part or a foreign obstacle, RapidSense can detect it in the defined volumes.

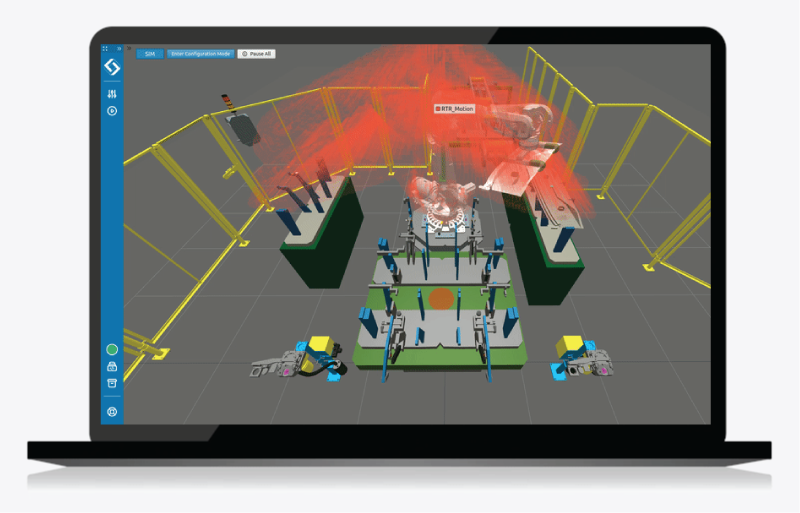

3. Detect and react

The last step is watching the robots in production adjust automatically to variable and known objects in 3D space. The unique connection between RapidPlan and RapidSense provides adaptability to variable parts and collision avoidance for unexpected intrusions within the workcell.

Stream Quality

Flexible multirobot cells

Build pallets nearly twice as fast, pick from the same bin with two arms, depalletize in a fraction of the time. With RapidSense, you can reduce system downtime and increase throughput, all while ensuring your products remain safe and undamaged.

Contact

Get in touch

Increase your automation intelligence.

Decrease wasted time. Get in touch.

Fill out the form or call:

+1.617.302.6330.