Milestones

The Schaeffler Group Selects Realtime Robotics RapidPlan Software to Optimize Its Use of Industrial Robots

Realtime Robotics Helps Automotive and Industrial System Supplier to Improve Throughput and Cell Automation

Optimizing Industrial Automation

In 2021, Realtime Robotics began working with Schaeffler’s New Production Concepts department (NPC) to support Special Machinery (SMB), which is developing and realizing individual turnkey production solutions. In this case, NPC functions as a pre-development department to identify, benchmark and develop new production technologies that can be used by SMB in the future, to help both internal and external customers improve the overall efficiency and effectiveness of their operations.

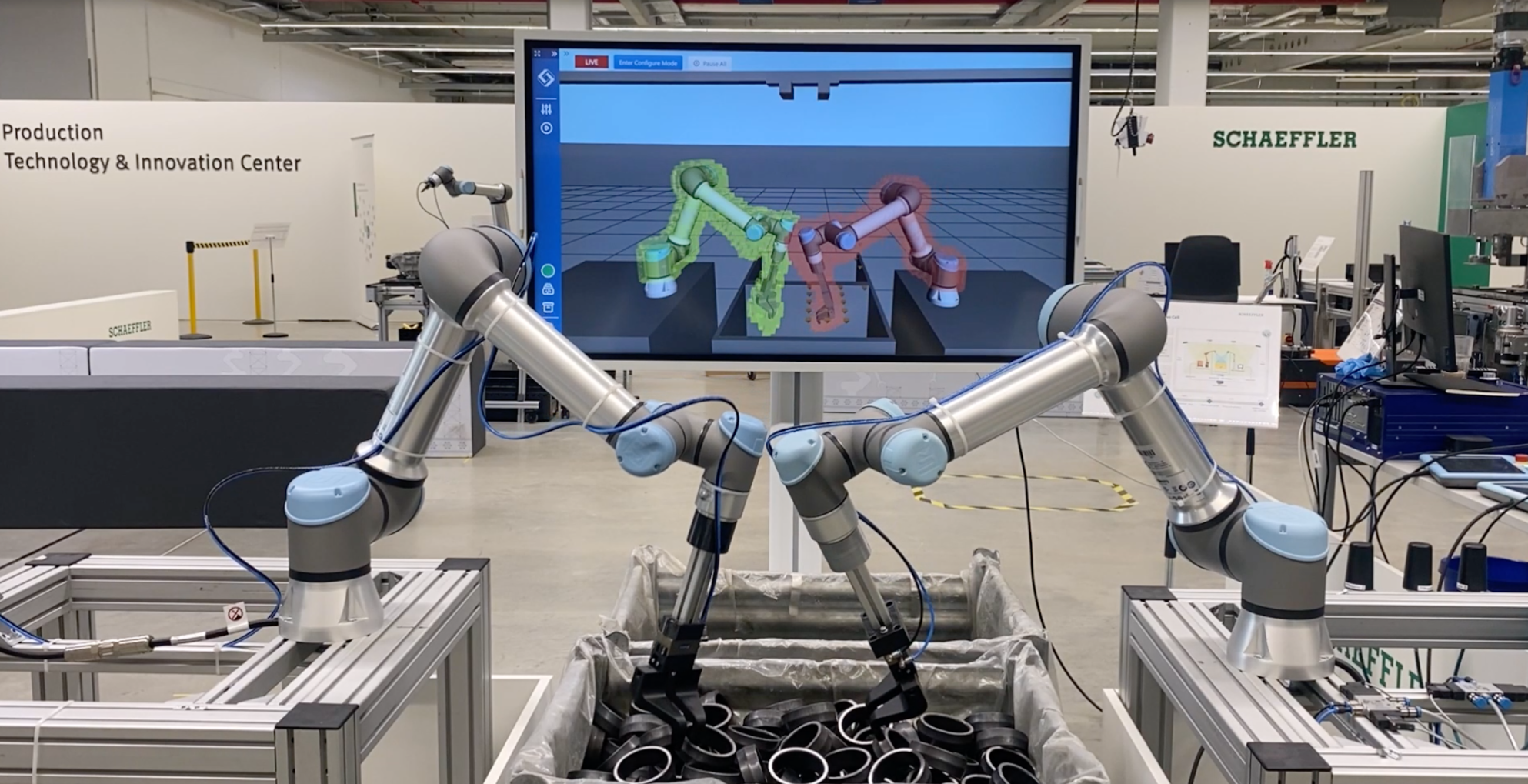

New Production Concepts learned of Realtime Robotics’ innovative motion control and collision avoidance software, RapidPlan, and wanted to test it thoroughly in a very complex and unpredictable environment to explore its potential benefits. This was done by building a simultaneous dual robot bin-picking application in a shared workspace.

The initial goal of the application was to optimize their use of robotics by having two robots pick parts from the same bin, collision-free. Previously, this operation was only able to be done by one robot at a time, or by two robots in a separated workspace or each using a separate bin. Because the robots needed to be separated to prevent the chance of collisions, additional space was required.

In addition, when multiple robots are in use, and the parts are in an unpredictable location each time, the robot programming needs to be very precise and complex, as the location and actions of each robot need to be tightly managed. The results exceeded expectations, showing that running two separate robots together would dramatically improve the bin-picking time.

Improving Production Speed

The New Production Concepts team had reviewed other potential solutions and found them unable to do more than improve the action of a single robot at a time. This is why Realtime Robotics’ RapidPlan software was so attractive to Schaeffler. The promise of two robots working together in close quarters without collision was tantalizing. Not only could production be sped up, and more complex cells be navigated, but the available space on the assembly line floor could be better optimized to increase production.

Traditionally, to avoid collisions, each robot has to wait for the other one to complete the task prior to moving into its space. With RapidPlan, you can truly capitalize on maximum productivity by adding additional robots to your application. You don’t need interference zones, which limit robots from moving too close to other robots, because RapidPlan releases the robot space reservations as soon as they are completed, allowing all robots to work simultaneously and next to each other, picking and placing parts within close proximity. The required cell footprint can be shrunk significantly.

Results Exceed Expectations

Most would think that the addition of a second robot to operations would double throughput – but in reality companies typically only see about a 28-30% overall throughput increase. In the past, adding a second or third robot makes the programming that much more complicated, as you have to account for interlocks.

With RapidPlan, Schaeffler was able to improve throughput without significantly complicating the programming layers. They were targeting a 60% throughput increase, and the results far exceeded the expectations with an almost double throughput increase.

RapidPlan improved throughput dramatically for Schaeffler while eliminating the chance of time-consuming robot collisions. Needless to say, the team was thrilled with the results.

As a system integrator, you often have to use a range of simulation platforms and tools that are specific to the brands of robot being used. But, because RapidPlan is built to be robot manufacturer-agnostic, companies can use it to streamline their cell commissioning process.

In the past, operators wouldn’t know for sure if the simulated actions would match up correctly to real-life, meaning that rigorous and manual testing was needed. Schaeffler discovered that with RapidPlan they were able to quickly simulate the robot cell, gaining a holistic cell simulation that made it easy to plan out how the robots would move, with the simulation software being the same as what powered the real-life robot actions.

This has proven to be such a valuable feature that New Production Concepts is using it as a simulation tool and will further evaluate the technology in production as a potential tool for SMB. Plans are to put RapidPlan to work in a project where three robots would work together to build a bearing unit.

The Schaeffler Group

The Schaeffler Group is a leading global supplier to the automotive and industrial sectors. The company has been driving forward groundbreaking inventions and developments in the fields of motion and mobility for over 75 years.

With innovative technologies, products, and services for electric mobility, CO₂-efficient drives, Industry 4.0, digitalization, and renewable energies, the company is a reliable partner for making motion and mobility more efficient, intelligent, and sustainable. It manufactures high-precision components and systems for powertrain and chassis applications, as well as rolling and plain bearing solutions for a large number of industrial applications. It is one of the largest bearing manufacturers in the world, delivering them for a range of vehicles from cars, to airplanes, to space shuttles.

The Schaeffler Group generated sales of approximately EUR 13.9 billion in 2021. With around 83,000 employees, Schaeffler is one of the world’s largest family companies. With more than 1,800 patent applications in 2021, Schaeffler is Germany’s third most innovative company according to the DPMA (German Patent and Trademark Office).