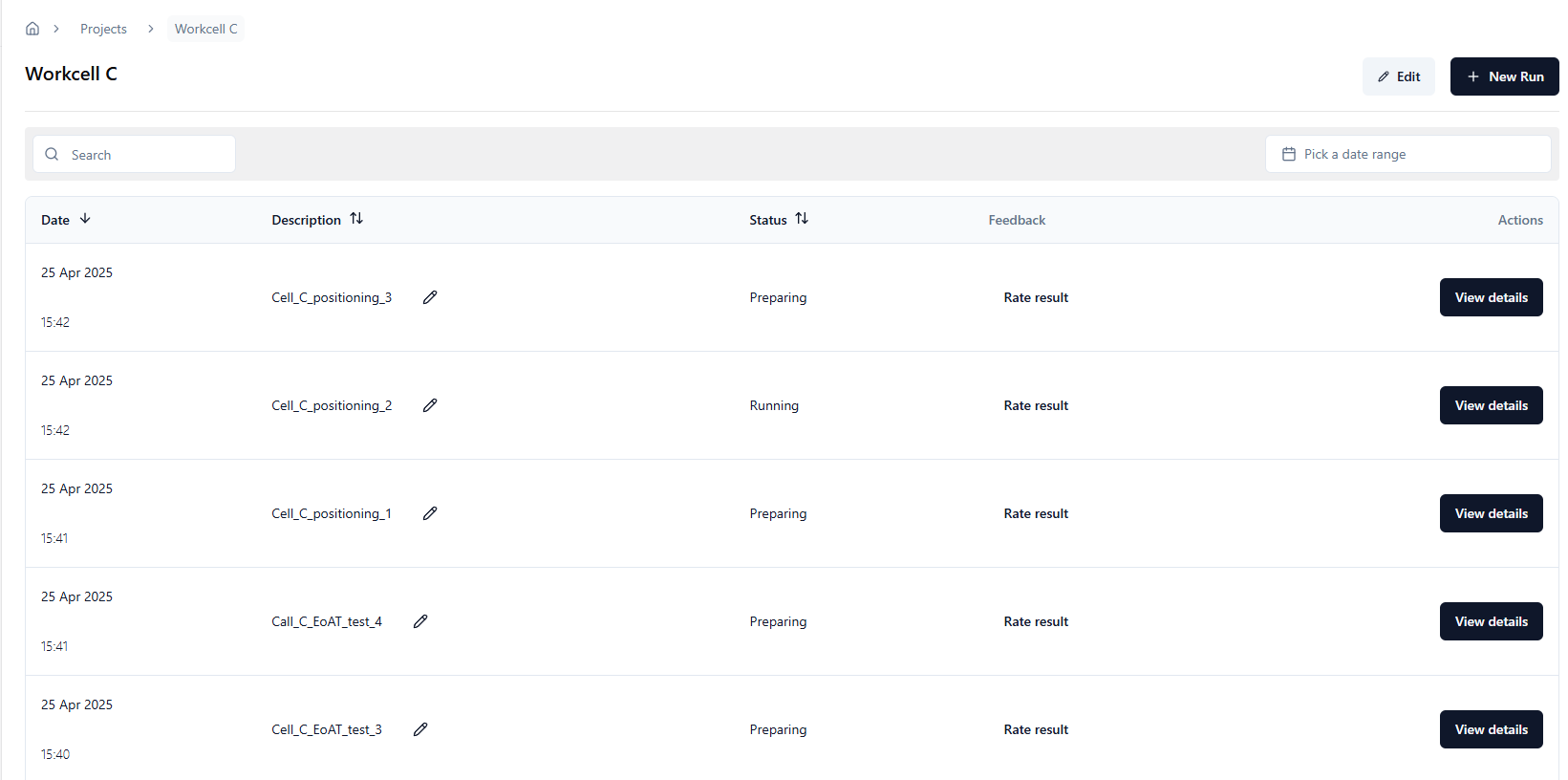

Have an infinitely scalable motion planning expert available to you at the press of a button. Harness the power of cloud computing to solve problems in parallel with Industrial AI.

Like the revolution in computer vision or writing, you can now supercharge your motion planners to get more done with their limited time.

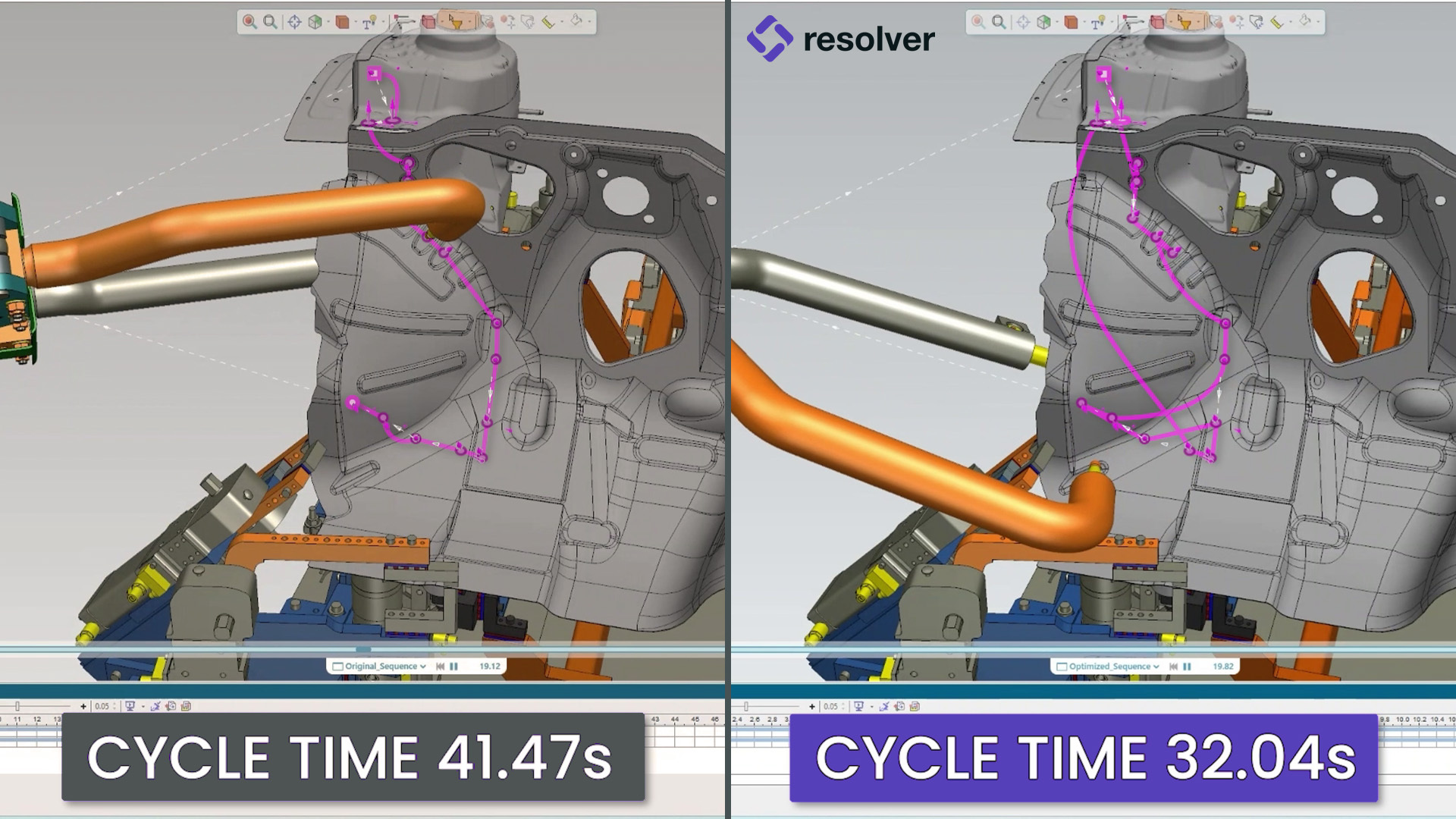

Your team won’t just work faster—Resolver delivers results beyond what humans can achieve.

In many workcells, the solution space has 27 zeroes. Exploring it fully would take a modern computer a million years.

Resolvers industrial AI finds competitive paths in minutes and keeps improving—closing in on the global optimum while humans are still sketching.

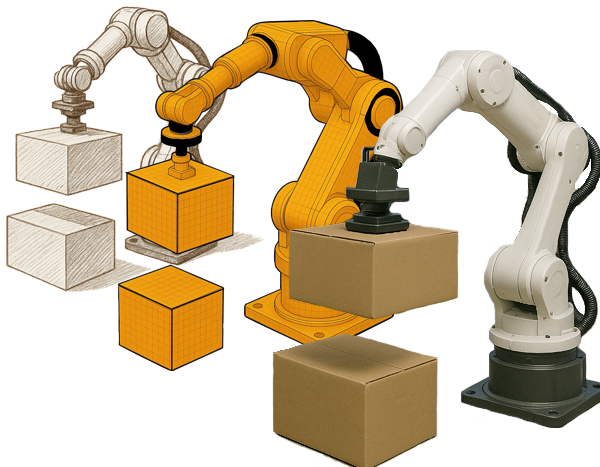

With Realtime’s software, you can move from concept to working automation at shocking speed. By combining RapidPlan with a state-of-the-art vision library, tasks like picking and placing boxes become effortless.

Save money

Dramatically reduce required simulation, OLP and even design hours.

Save lead time

Deploy faster and cut production lead times by 50%.

Get better results

Hit production targets in a fraction of the time, every time.

Get better business

Beat out the competition and deliver on every promise.