CASE STUDY

Unlocking Faster ROI

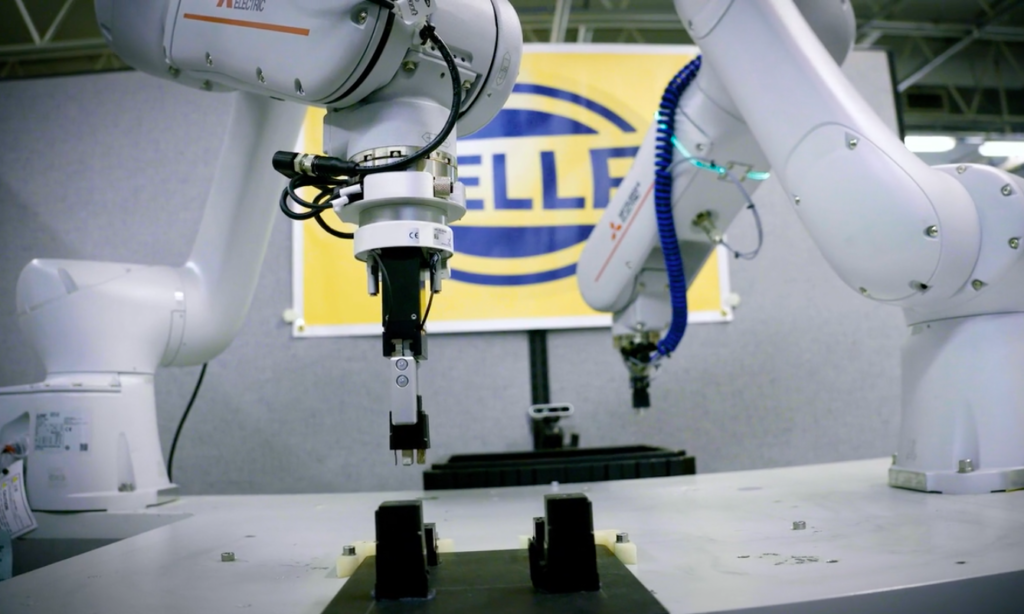

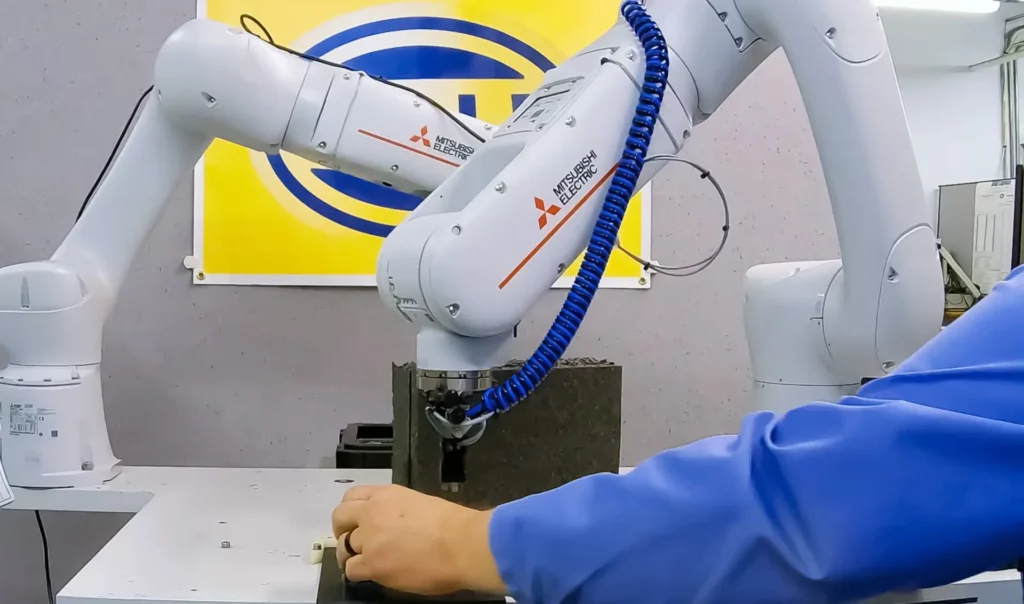

Speed, agility and flexibility are critical in order to produce products for vehicles in a timely manner to capitalize on the latest models, transportation trends and styles. Parts suppliers like HELLA Electronics Corporation also need to be able to change the products they produce quickly and easily as demand can increase or fall at a moment’s notice.

PROJECT GOALS

Wanted: Agile Automation

The company was looking to optimize an existing pick and place operation, with a lot of incoming and outgoing goods. Live collision avoidance, while rapidly responding to an unexpected operation or variable task was key, followed by dynamic work and obstacle avoidance. They were also looking for decreasing reprogramming, redeployment time and cycle time along with the cell footprint.

Read the full case study

Submit your details below to dive in