CASE STUDY

Unlocking Faster ROI

Speed, agility and flexibility are critical in order to produce products for vehicles in a timely manner to capitalize on the latest models, transportation trends and styles. Parts suppliers like HELLA Electronics Corporation also need to be able to change the products they produce quickly and easily as demand can increase or fall at a moment’s notice.

PROJECT GOALS

Wanted: Agile Automation

The company was looking to optimize an existing pick and place operation, with a lot of incoming and outgoing goods. Live collision avoidance, while rapidly responding to an unexpected operation or variable task was key, followed by dynamic work and obstacle avoidance. They were also looking for decreasing reprogramming, redeployment time and cycle time along with the cell footprint.

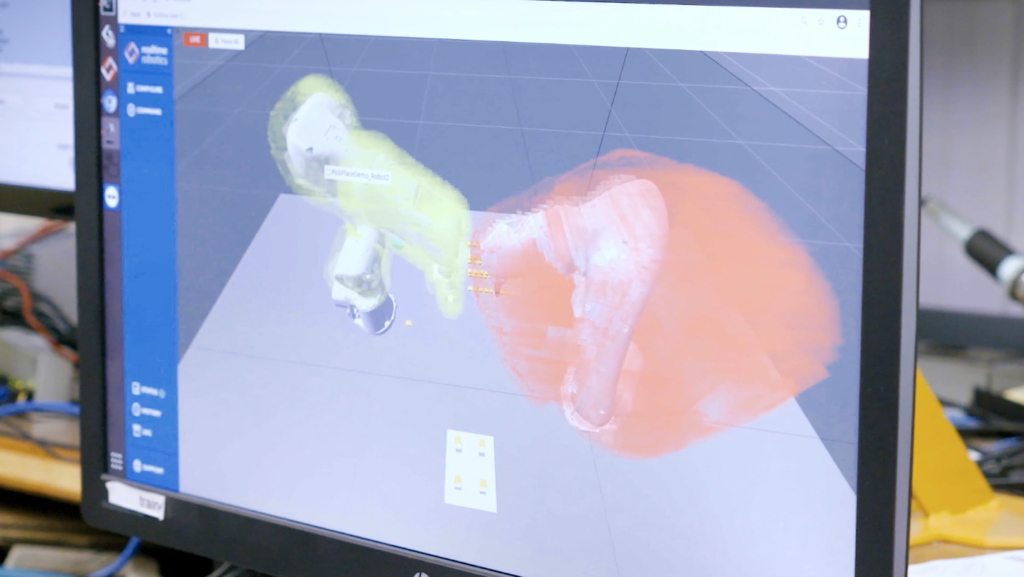

Rapid Autonomous Motion Planning

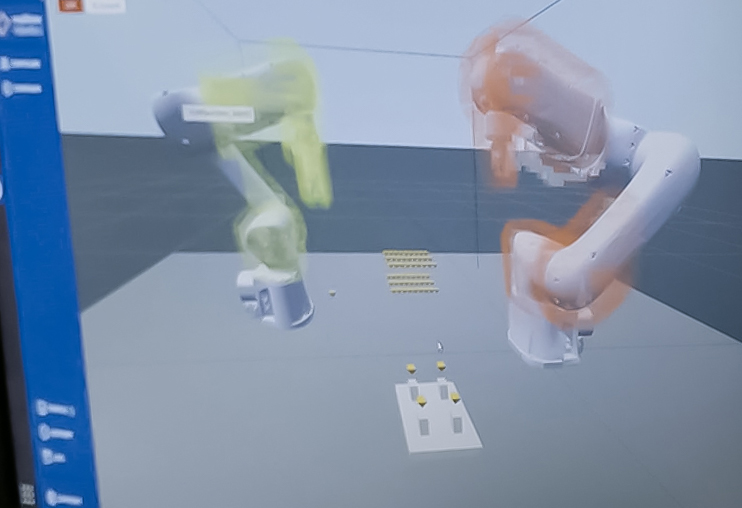

HELLA turned to Realtime to improve collaboration, motion planning and collision avoidance within its facility. As a close partner of Mitsubishi Electric’s, it was easy for HELLA to apply Realtime’s motion planning solution to its robots.

Realtime’s AI-driven software autonomously choreographs all robot movements, allowing multiple robots to work collision-free and collaboratively within a shared space without interference zones. Robots with Realtime’s technology are empowered to function seamlessly across many deployments, with minimal programming or re-programming.

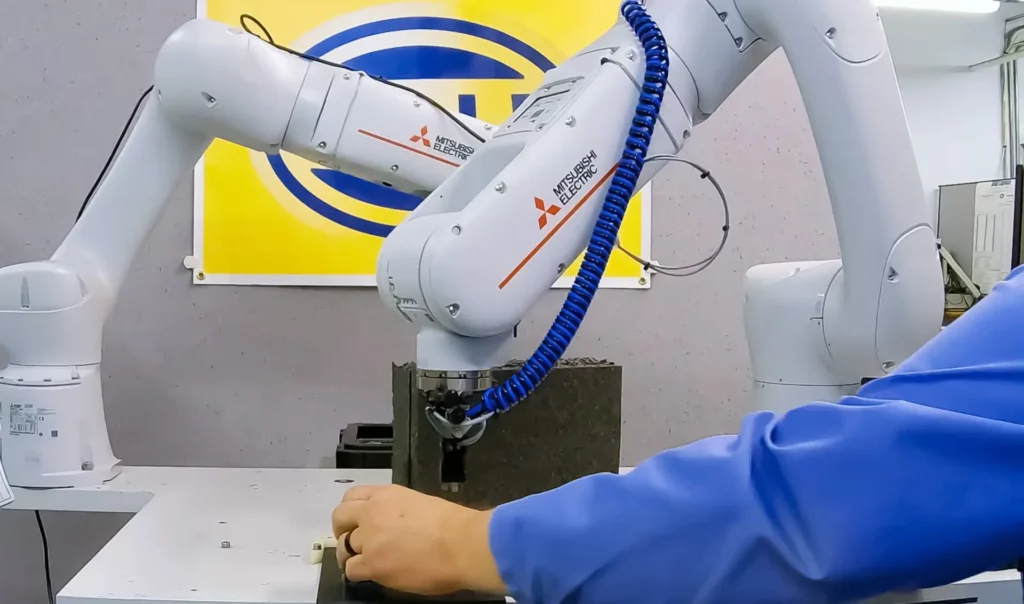

The company’s user-centric software allows cell specs to change in real-time. For the teams designing, engineering and fine-tuning the smart automation, the process becomes much simpler with the addition of Realtime’s software. “If you’re working with multiple robots, more than one robot in tandem, programming becomes the solution – and deployment becomes so much quicker and easier because, as the engineer, I don’t have to do all the programming,” said Ralph Barbre, Automation Engineer at HELLA. “I just have to know where the robot is going to pick, where it’s going to place and Realtime Robotics takes care of the tracking of the robot, the paths of the robot for me and I don’t have to be concerned about them colliding with each other.”

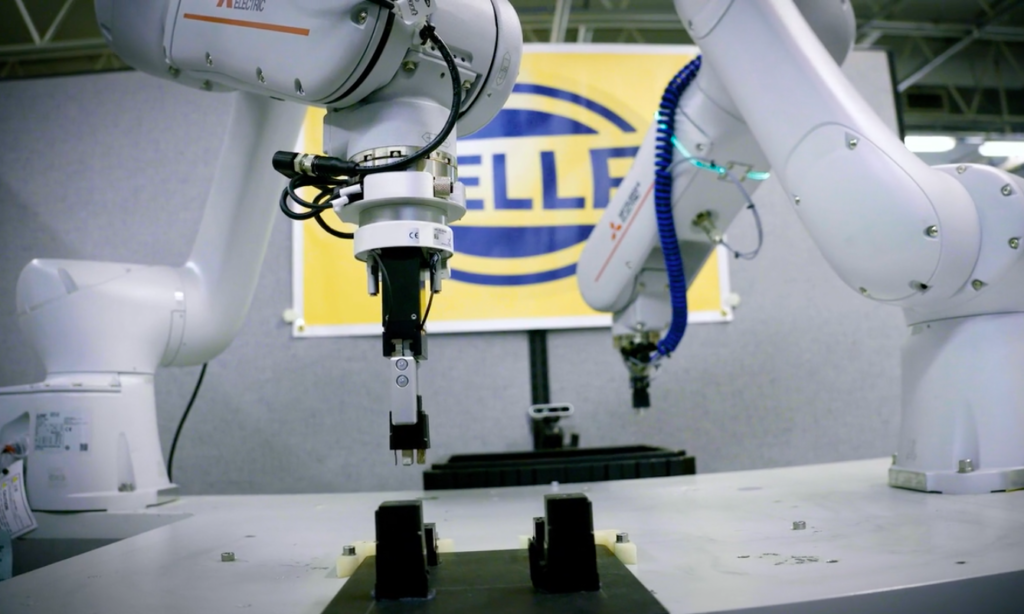

ASSISTA Series Collaborative Robots

Collaborative Robots must be able to handle jobs that require more precise, controlled and even delicate movements within an ever-changing, fast-paced environment. HELLA had a long-standing partnership with Mitsubishi Electric, who provided HELLA with ASSISTA Series of collaborative robots, easy-to-maintain collaborative robots, which were also very easy to control. With substantial load capacity and precise movement capabilities, the ASSISTA Series of collaborative robots could help HELLA realize more efficient production through visual programming. Mitsubishi Electric integration and quick, easy deployment in multiple applications also reduces the total cost of ownership of robot systems. Collaborative Robots must be able to handle jobs that require more precise, controlled and even delicate movements within an ever-changing, fast-paced environment.

Project Results

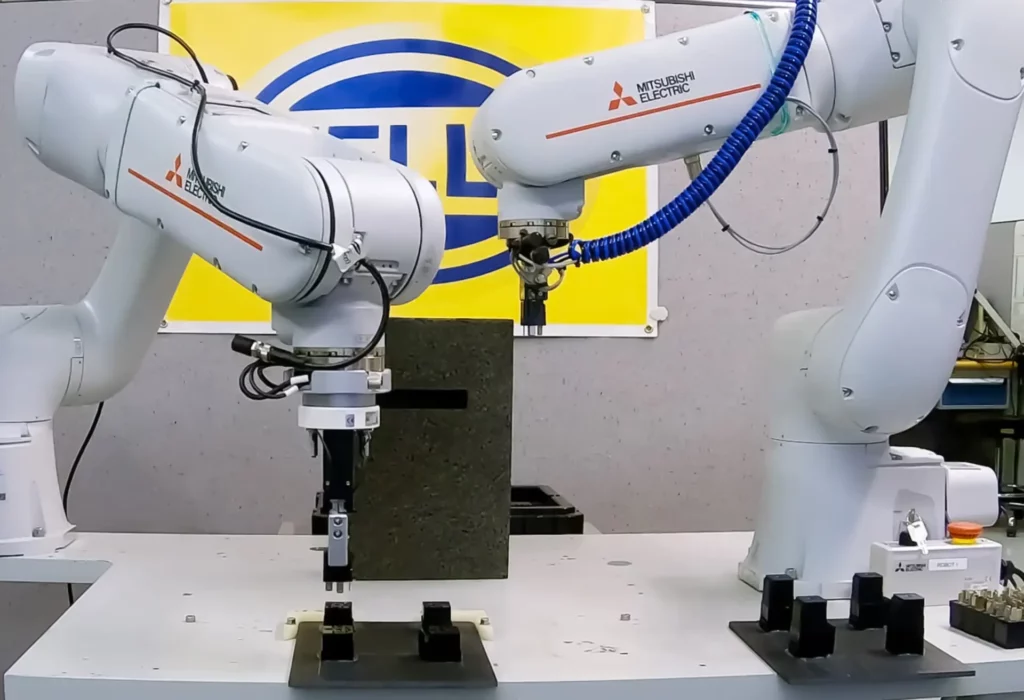

The integrated Realtime Robotics and Mitsubishi Electric solution provides HELLA with state-of-the-art collaborative robots, on-the-fly robot movement planning, collision avoidance, deployment time savings, improved throughput, reduced cell footprint, reduced cycle times and overall increased flexibility.

As a result, Mitsubishi Electric and Realtime transformed the usual pre-deployment time required for commissioning. The robot movement validation process often takes weeks and can be now done in an offline setting without impacting the production environment. “We’ve been able to really debug the whole cell in an offline manner, talking about implementing it within a day or two,” said Curtis Garrard, Head of Technical Services at HELLA.

HELLA benefits from having the technology at its disposal to be scalable and rework existing production lines as needed. “One of the benefits of the Realtime Robotics platform with Mitsubishi hardware is its ability to drop in nearly any application that’s going on. So whether that’s a new line designed out of the gates or an existing line that has personnel on it, or maybe it had some legacy automation that you wanted to improve, it literally can function in any of those systems you drop in,” said Tim Kalhorn, Channel Account Manager, Mitsubishi Electric Automation, Inc.

As new products are needed HELLA has the ability to reuse prior capital investments to address current customer needs is a massive competitive advantage. On top of that, they also help HELLA provide these products quickly and at a reduced cost than some competitors.

The Realtime Robotics solution allows the robots to work dynamically around one another in a much more cohesive work environment, so you do get closer to the actual realization of cutting your cycle time in half.

AUTOMOTIVE PARTS SUPPLIER

About HELLA

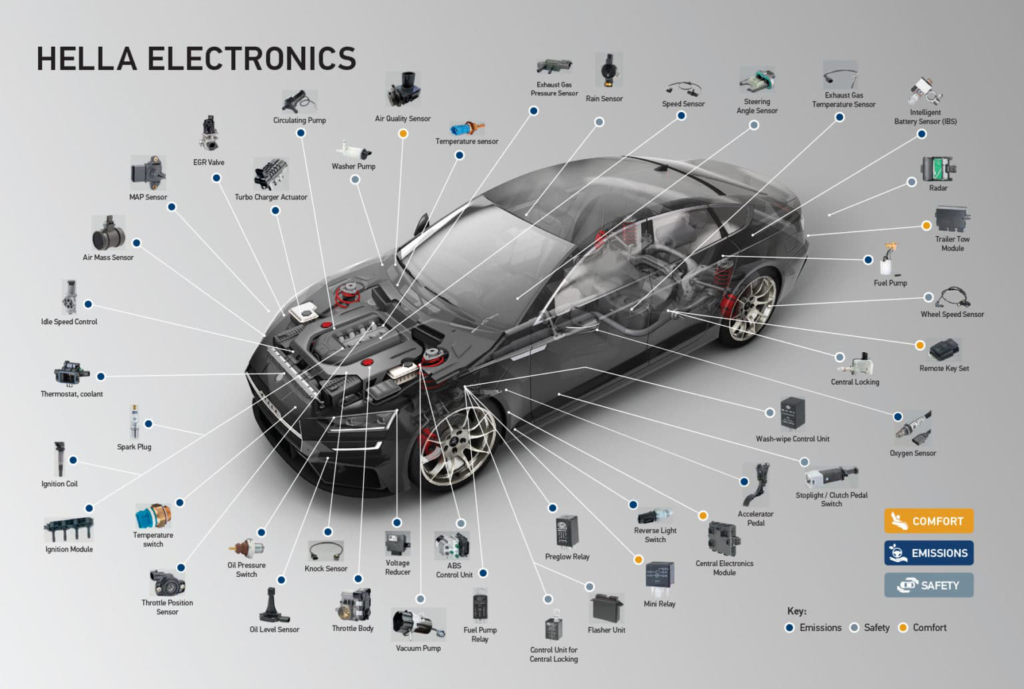

HELLA Electronics Corporation is an international tier one automotive parts supplier, based in Germany, with more than 40,000 employees worldwide. They are known as an innovative industry leader, specializing in automotive lighting, electronic components, aftermarket products and special applications.

REALTIME ROBOTICS

Transform Your Automation

Realtime’s products enable multiple robots to operate autonomously at full speed in unstructured and uncaged environments. Companies are empowered to automate more processes by removing engineering complexity and reducing cycle time, lowering overall expenses, driving greater operational efficiency and significantly improving ROI.