Today, Realtime Robotics is excited to share its values, mission and vision with the world.

With the roll out of these messages, we wanted to take a moment to share why now was the correct time for us to look inward and define what it means to be a part of the Realtime team. To get to this point, we worked closely with the most important aspect of Realtime Robotics – its employees. Our team makes our company what it is today, and what it will be.

We’re very proud of the outcome – and feel it will shape corporate culture while laying the foundation for the future.

To shed some light on the process and what these values mean to us all, we recently sat down with several Realtime employees. Here’s what they had to say.

Timing

There are moments in the lifecycle of a startup when it’s “time to grow up.” When you reach a certain number of employees. When you expand to a larger office. When you sign your first customer. When you bring a product to market. These are all part of the growth and evolution of a startup company.

“The usefulness of this is to give everyone a set of rules or a framework to think through how we should be working together,” said Pete Conti, Director of Software Quality Assurance for Realtime. “For instance, what is our vision? Where are we headed? How do we want to get there? And what are we working towards now? When we’re working, what enables us to have success?”

Vladyslav Khyzhniak, Realtime’s Software Architect, added that “…the value exploration work…will help keep everyone aligned together on common values and goals. It will reduce employees’ frustration over disagreements, flourish a positive and healthy environment over time, and allow taking critical decisions in the right direction faster and more efficiently.”

Process

Establishing core values that reflect who your company is, and what it is striving to be, is more than just checking off the next height on the growth chart. Company values need to be a framework for collaboration; for both the day-to-day operations and the future growth of the company.

Molly Costa, the company’s Operations Director, enjoyed the process of establishing these values, and when reflecting on the task, pointed out that “…we all have opinions about the company we work at. Getting a safe place to talk about this together and see how many similarities we all have about how we want the company to function, and how we want to work with each other, was great…now, we will have the ability to point to them, and use them for everything from hiring to setting quarterly goals. I think it’ll just help the conversation by having those common values to fall back on.”

Echoing those thoughts, Chidi Imala, Robotics Software Engineer, described the process of creating these values as a valuable undertaking that “…brought people from different backgrounds into one room,” so everyone could see “…how people view things and understand what working together and collaboration means” to everyone. “It was a good team building exercise,” he felt, “as it created a sense of togetherness that spurred practical things to be rolled out.”

Values

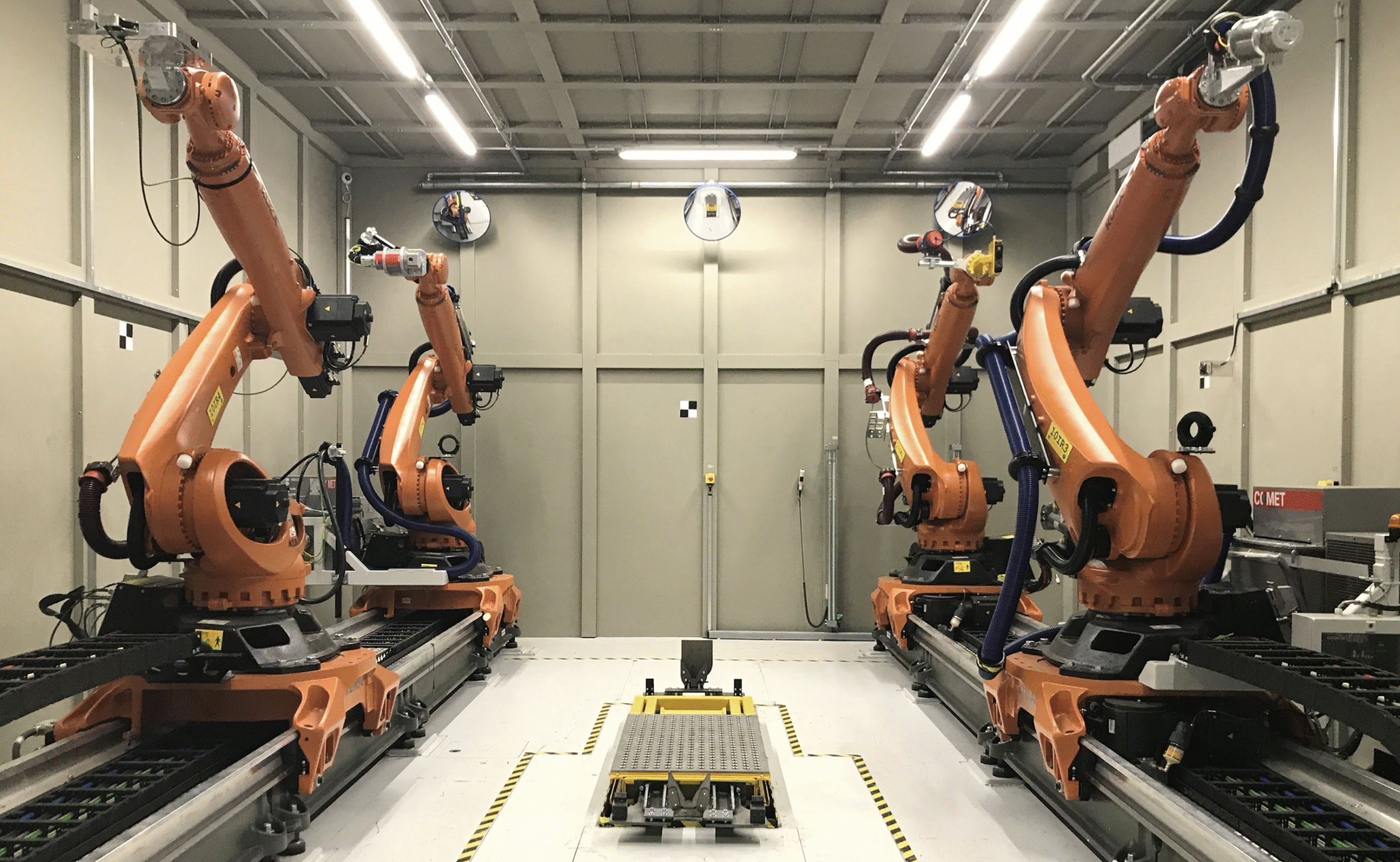

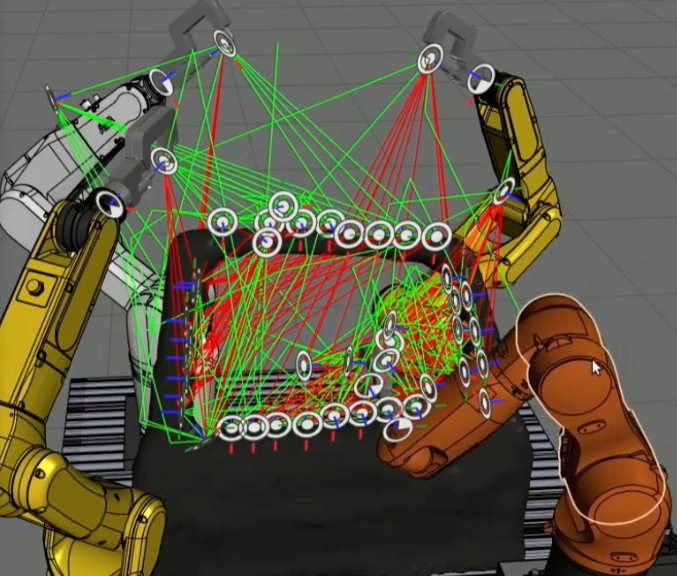

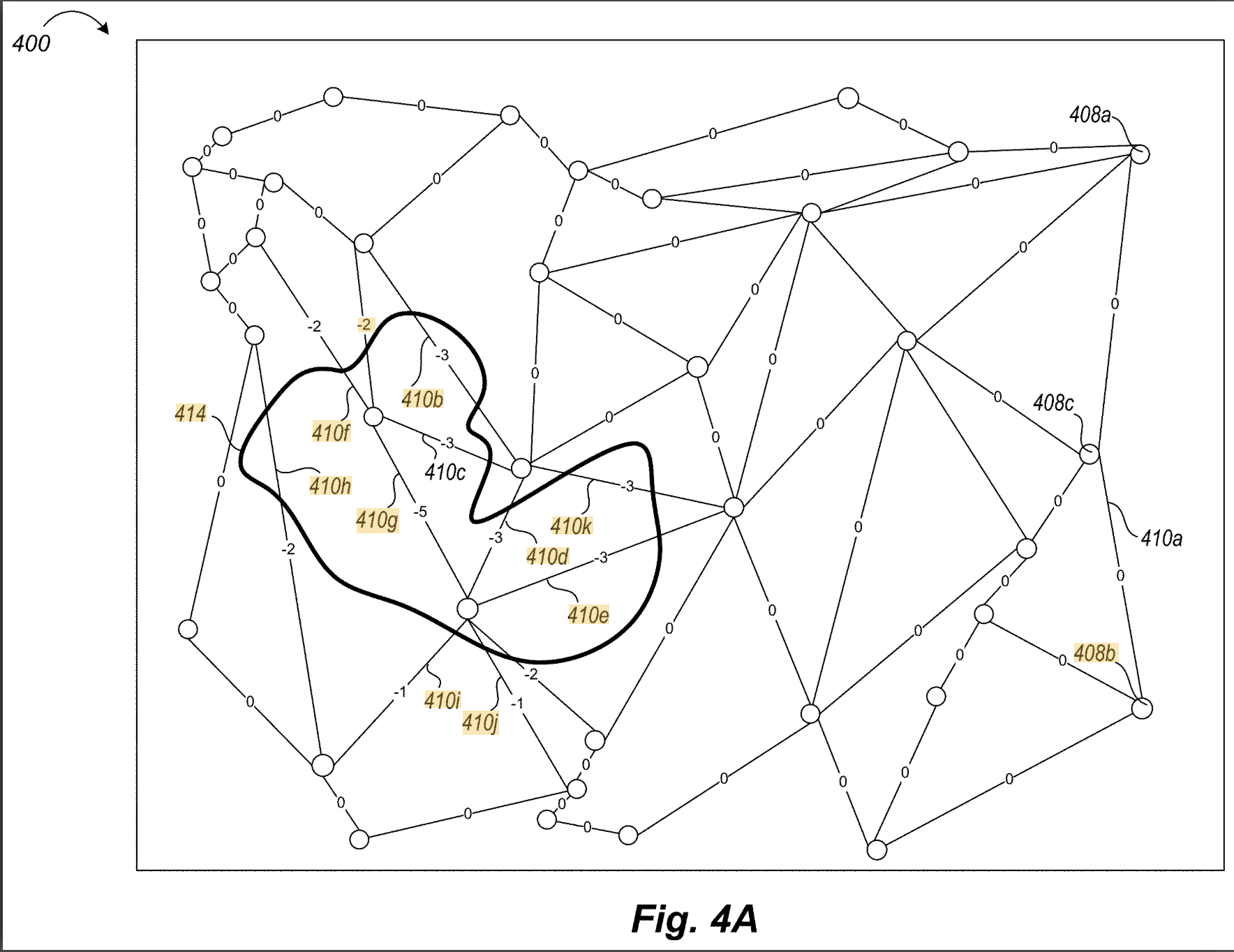

Realtime Robotics vision is to “free the world from dull and dangerous tasks” and our mission is “to make industrial robot automation simpler, better and faster.”

Our company values reflect who we are currently, where we came from, and where we are going. These easily flow out of our vision and mission statements, and resonate with each employee. Five company values define Realtime Robotics:

- Radical Transformation – We lead revolution via practical solutions.

- Actionable Accountability – We build trust by holding ourselves accountable and creating actionable solutions.

- Passion for Collaboration – We embody trust and respect and embrace working together.

- Invested in Transparency – We are committed to openness about our shared mission and risks.

- Driven Through Feedback – We all continuously use internal and external feedback to advance.

Values in the Workplace

Feedback and transparency are critically important; they will help guide each of us to improve and overcome any issues experienced along the way. At the same time, when you work as closely with your customers as we do, there is another, just as important meaning behind the values of feedback and transparency. Maintaining a spirit of collaboration with the team that will actually be using our product – and inviting them to be transparent and share all feedback with us – really helps to make sure we’re not going in the wrong direction.

We spoke with our group of employees about which values stood out and were the most important to each of them. Vladyslav said that he felt the values were all equally important and exciting together. “Some of the values are like the wheels and frame of the car, while others are like the engine and steering wheel. While some are ‘supportive,’ others are ‘driving.’ If you remove one value, other values will lose their exciting property.”

When asked the same question, Chidi called out the values of Passion for Collaboration and Actionable Accountability as those that meant the most to him. “I liked actionable accountability specifically because it has a proactiveness and practicality about receiving and asking for feedback. I liked the intentionality of continuous development and improvements…I can look at this value and do something with it. I also think I just like collaboration in general, as we want to create an atmosphere where we can work together and help each other…honestly and transparently. Giving feedback as a whole creates a dynamic company where everyone’s growing. It’s obvious that will have an impact on our products as well, because the more we can practice those values in terms of collaboration, feedback, and clarity in deadlines, then the more the company as a whole is healthy, and employees will be able to create excellent products.”

Values in Product Development

Our vision and mission has driven the development and release of our RapidPlan software – and the formal establishment of our values will only help improve how we create, build and bring products to market. Our team identified several problems in the industrial robotics space, namely the fact that the industry had been static for a very long time. Manufacturing and logistics companies had gotten used to operating the same way they always had, meaning there was consistency, but very little opportunity for improvement. To be more efficient, improvements needed to be made to improve the return on investment. That is where Realtime Robotics came in.

Molly summed this feeling up best when she said that “…the Passion for Collaboration value is very representative of how we’ve built our product thus far. So much of it has been almost co-designed with lead customers in mind – and that will continue moving forward. There’s no reason to make assumptions based solely on market research. Sometimes, it really helps to collaborate with the team that will actually be using the products. So while the use case may change over time, working with our ideal customers really helps to make sure we’re not going in the wrong direction. And then, maybe even more importantly when it comes to the product, we have to keep the Radical Transformation value in mind, because we don’t want to just make things slightly easier for our customers, we want to make it astronomically easier for them and better and faster. So I think those values are at the core of our product.”

She also shared that the Driven through Feedback value is a really important one to keep working on, as “…I think it’s something we’re already pretty good at. It’s kind of self-explanatory, but we take that very seriously, where we’re not just taking feedback internally or from the market. We’re a company that works really closely with our customers. We have a lot of guiding partnerships with big customers that have really impacted our product in the best ways.

“The most important thing for me is how we actually put these values into actions, and what it means for an action to violate or stay true to the value,” added Rebecca Jung, Manager of the Validation Engineering Team. “Putting these into writing for me is more important than the value itself, because it actually makes you know what bad behavior and good behavior is, so people can actually apply them. Without that it’s like, ‘what is passion for collaboration? How do you actually do that in real life?’”

Overall Impact

Employees have already seen the values have a strong, positive impact on the ways the company operates day-to-day. Realtime’s COO, Matt Coady,felt that “…one of the things that is sort of challenging about being remote is that whole sense of team and purpose – and that is definitely something that I think a lot of companies are wrestling with; if you’re adopting a distributed workforce model, it is harder to create a closely knit sense of team. This is an example of something we can do as an organization while still giving people the freedom to choose whether they work at home or remotely, and increase the feeling of kinship within the company. A sense of a bigger purpose.”

Molly chimed in that she’s “…already seen a lot more people trying to honor these values in their meetings, and using them as a way to create a break from the meeting, to talk about how we can honor X value. Even though I think it’s something we were already pretty good at, I’ve certainly heard the phrase, ‘in honor of being transparent’ more. The actionable accountability value has also come up more, as it empowers employees to speak up about blockers or failures, because it’s expected and safe to do so.”

These values do “…give you a bit of a backdrop to say something that would be a bit difficult to express otherwise,” added Matt. “Whether it’s conveying difficult news or sharing an opinion that you know isn’t going to be popular, we all agreed that we want those things, right there, in our company values.”

A Strong Foundation

Aiming to be a catalyst for change in an industry – especially one that hasn’t traditionally moved quickly towards new technology – is not easy. But it isn’t impossible.

When your goal is to radically transform something – and you’re moving fast – everyone needs to be on the same page and striving for the same endgame. Vladyslav put it best when he said: “…company values are like oil. If it’s the proper oil for proper parts and functionality, it will reduce the tension between parts and direct the force into useful energy. However, if it’s done poorly, it may clog and halt the system.”

These values honor who Realtime is as a company and our goals, while helping us all keep the big vision in mind.