Solution Recognized for Ability to Eliminate Production Bottlenecks and Improve Manufacturing Productivity

BOSTON – October 3, 2024 – Realtime Robotics, the leader in collision-free autonomous motion planning for industrial robots, today announced that it has been named the Gold Winner of the 2024 Merit Awards for Technology in the Robotics category.

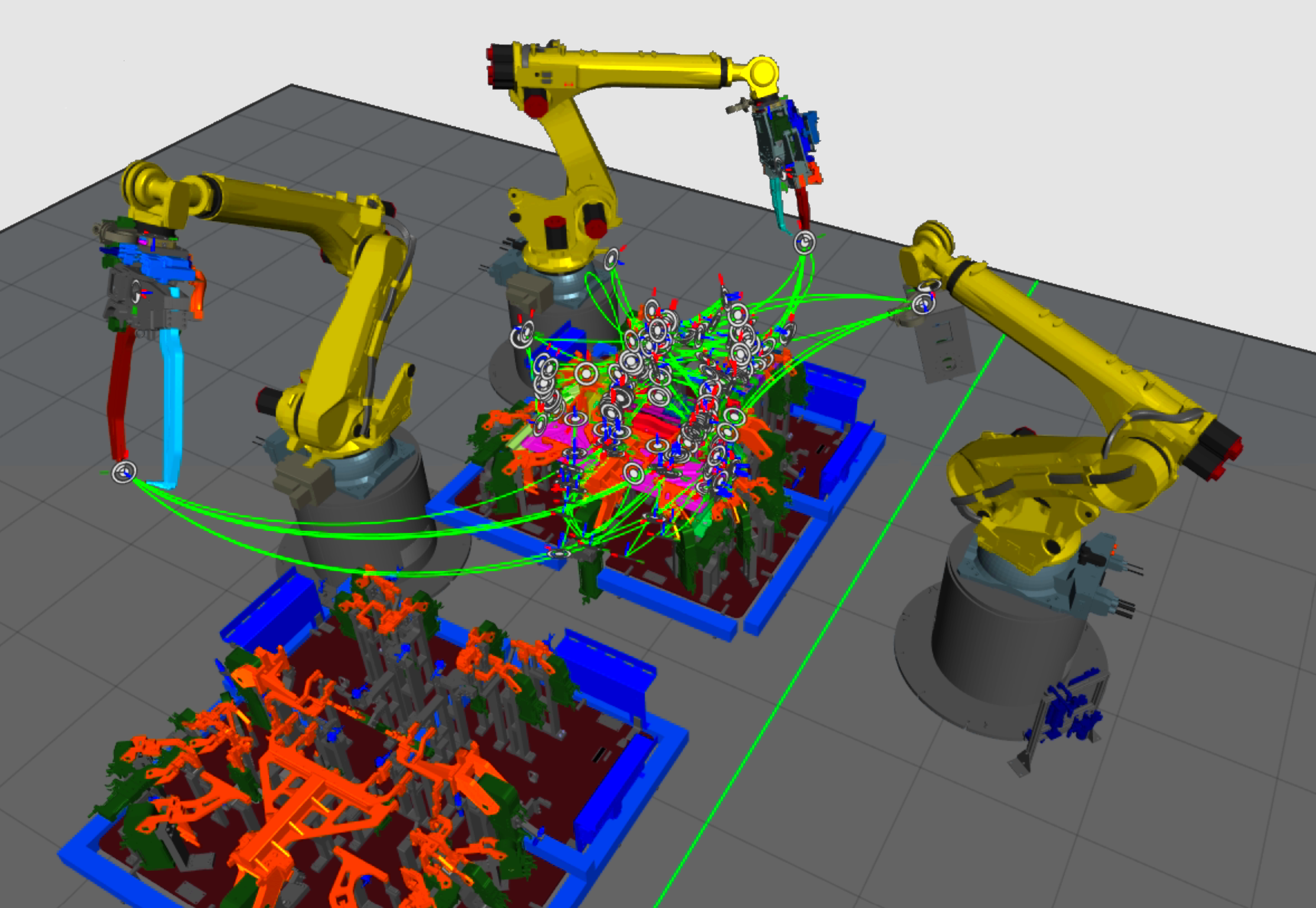

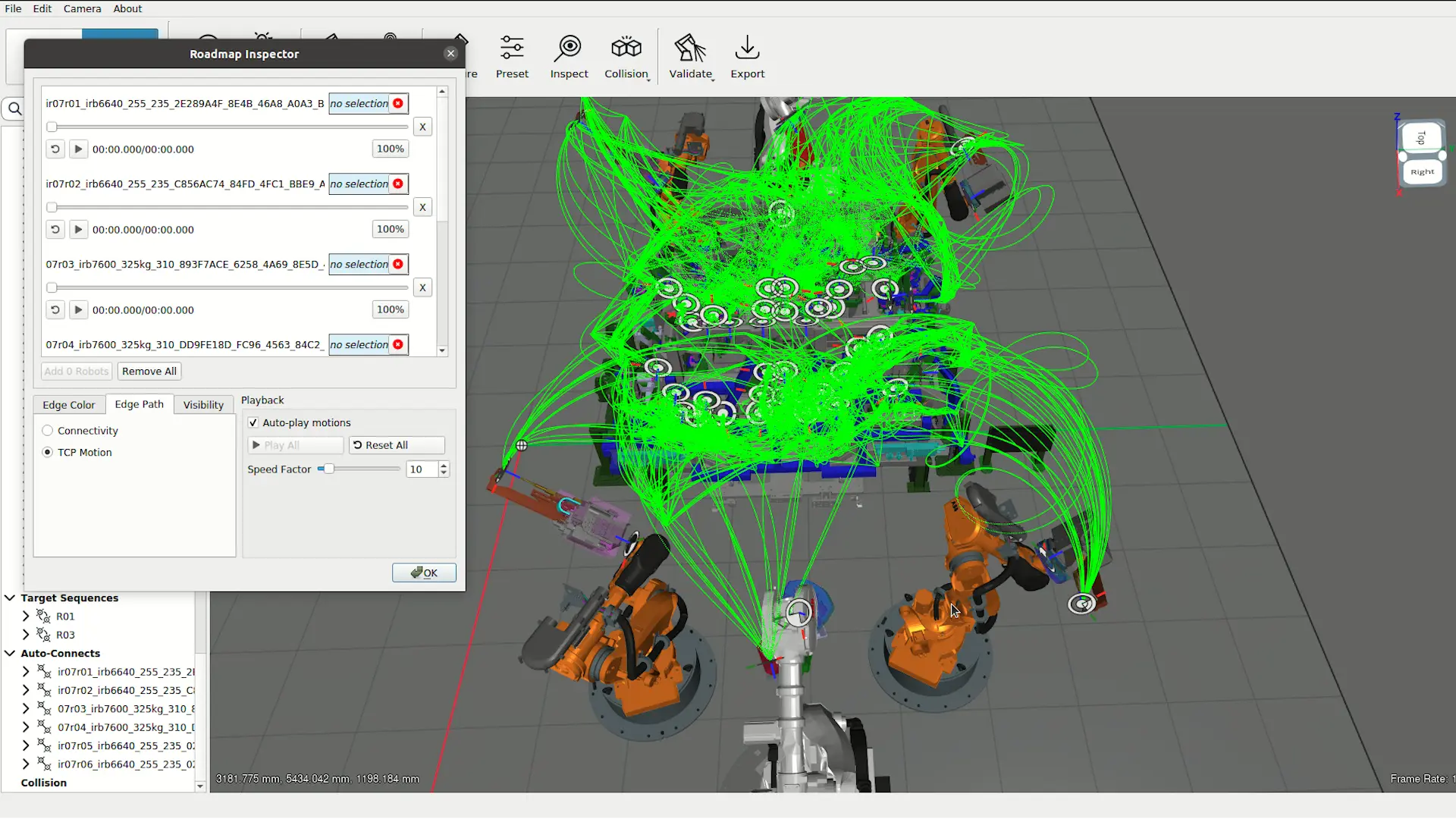

Realtime Robotics’ Optimization solution uses a combination of proprietary software and experienced robotics and application engineering insights to drastically improve a manufacturer’s overall productivity by reducing a workcell’s cycle time. The solution analyzes a customer’s existing digital twin, identifying bottleneck areas and recommending improvements based on desired parameters. This can all be done without interfering with ongoing production efforts.

“We knew that some of the biggest challenges for manufacturers were assembly line bottlenecks that increased cycle time and slowed productivity. While it was commonly understood that improving robot movement plans and paths could break a bottleneck, it was also a manual, time-consuming process that few organizations had time for,” said Peter Howard, CEO of Realtime Robotics.

“We developed our Optimization solution to automate the process, rapidly evaluating and testing out potential robot movements and actions alongside different configurations, ultimately finding the solution with the shortest cycle time. This award is a testament to the hard work of our team in bringing a solution to life that can so dramatically impact a manufacturing operation.”

Customers need only send Realtime their simulation CAD file for the bottlenecked cells. The company’s engineers will then use proprietary algorithms and expertise to optimize the workcell in just days, rapidly generating and testing hundreds of thousands of potential robot paths, sequences, poses, end-of-arm-tool rotations and complex robot interlocks, until cycle times are reduced with better robot paths and sequences. Once the results are validated, they can immediately be transferred to the production floor.

Realtime Robotics Optimization solution was also recently named the 2024 winner of the prestigious Innovation and Entrepreneurship in Robotics & Automation (IERA) award, presented annually by the IEEE Robotics and Automation Society Industrial Activities Board and the International Federation of Robotics (IFR). Customers including Volkswagen Commercial Vehicles and Valiant TMS have already dramatically cut down robot programming time and realized improved cycle times as a result of working with Realtime Robotics.

For more information on how Realtime Robotics’ Optimization solution can help reduce workcell cycle time and improve manufacturing productivity, please view our recent video here or visit https://rtr.ai/solutions/optimization/.

The 2024 Merit Awards for Technology were judged based on submissions that represent the best in current and next-generation innovations and technologies. To see the full list of winners, please visit: https://www.merit-awards.com/winners-technology-2024.

About Merit Awards

Designed to recognize the efforts put forth by global industries and the markets they serve, the Merit Awards will acknowledge companies that have contributed to the continued growth of the market. The Merit Awards are judged by industry executives, Merit Awards staff, members of the media and consultants. For more information please visit our website at http://www.merit-awards.com.

About Realtime Robotics

Realtime Robotics is the leader in automatic, collision-free motion planning for industrial robots. Its innovative technology generates optimized motion plans and interlocks to achieve the shortest possible cycle time in single and multi-robot workcells. The company’s solutions expand the potential of automation, empowering multiple robots to work closely together in unstructured and collaborative workspaces, reacting to dynamic obstacles the instant changes are perceived. Learn more about Realtime Robotics here, watch its technology in action here and connect with us on X and LinkedIn.

# # #

For More Information

Jeff Drew

Public Relations, Realtime Robotics

P: +1.617.233.5109

E: jeffreydrew@rtr.ai