Generate collision-free paths with automatic interlocks in milliseconds.

Respond to changes in real time through dynamic motion planning.

Return robots to their home position during breakdowns or E-stops with Autohoming.

Motion plan for any number of robots in proximity to one another.

Command and control any robot with robot agnostic signaling.

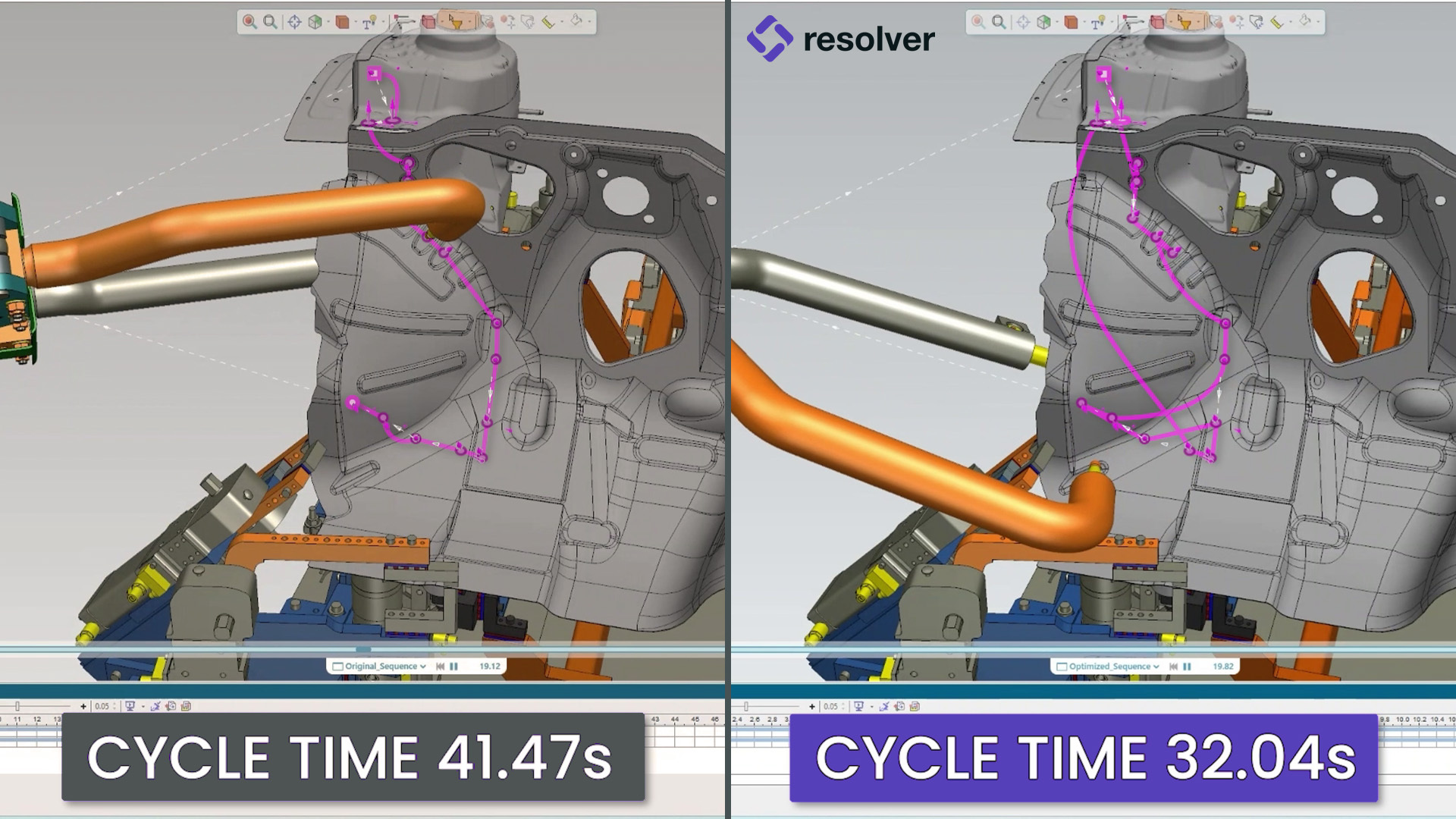

Automatically generate smooth, fast, and safe paths.

Cut motion development time by 90%. Develop your kinematics in days, not months.

Deploy without writing a single line of motion code. Only run RapidPlan on a computer, no programming of robots or teach pendants.

Recover from errors and get back on track in minutes — no manual fix needed.

Use any robot brand or switch brands mid-project without breaking stride.

Add sensors to react to new obstacles in real time using sensor data.

Get up and running in record time with RapidPlan

Run a palletizing robot with minimal code. RapidPlan handles real-time 3D data, collision avoidance, and dynamic motion planning—no need for months of coding. Fast to build, safe to run, and easy to scale.

Quickly Develop Cost-Effective Robot Prototypes

RapidPlan reduces programming effort, accelerates iterations, and saves on kinematics resources—helping you prototype faster with fewer resources. Develop robotics products quickly and efficiently with RapidPlan as your motion partner.

Solve Kinematics Challenges for Customers in Real-time

For dynamic, complex tasks like inspections or touch-ups, RapidPlan reduces programming time, risk, and cost. Quickly build adaptive kinematics solutions that impress customers and accelerate factory and site acceptance.

RapidPlan controls the robots based on what your software asks of it, taking into account sensor data in real time. This works for any number of robots and truly reacts to real-time events.

Your software controls the robots but gets path plans from RapidPlan to use at the appropriate time. This is easy to pipeline for optimum performance and provides a fallback plan for robot control with RapidPlan as a motion advisor.