iREX RTRブース (W4-61) でResolverの体験型デモを展示

BOSTON & TOKYO–(ビジネスワイヤ) — iREX 2025 — 産業用ロボットの自動動作計画、リアルタイム制御、最適化のトップランナーであるRealtime Roboticsは本日、iREX 2025でのResolver日本市場デビューをアナウンスしました。Resolverは同社のクラウドベースソリューションで、ロボットセルの設計、動作プログラミングとコミッショニング作業を効率化します。それにより、新製品・新機種の市場リリースサイクル(Time-to-market)を高速化し、ニーズ適合リスクやコスト負担を大幅に削減します。

それに加え、Resolverの新機能を初公開します。これによりエンドユーザーの業務フローがさらに効率化され、サポートするロボットモデル数も大きく拡大されます。Realtime RoboticsはブースW4-61にて、SIEMENS社 Process SimulateおよびVisual Componentsと統合された体験型デモを展示する予定です。

「製造業企業は、より少ないリソースで高い生産性を達成するプレッシャーに日々直面しています。それは、グローバル市場で勝ち抜くために、安定的かつ効率的なものづくりが不可欠だからです」

Realtime RoboticsのCEO、ピーター・ハワード氏は述べています。

「当社の独自ソリューションResolverは、従来よりもはるかに短いサイクルで新製品を市場へリリースすることを可能にします。このたび、日本の皆様にResolverを体験いただけることをとても楽しみにしております」

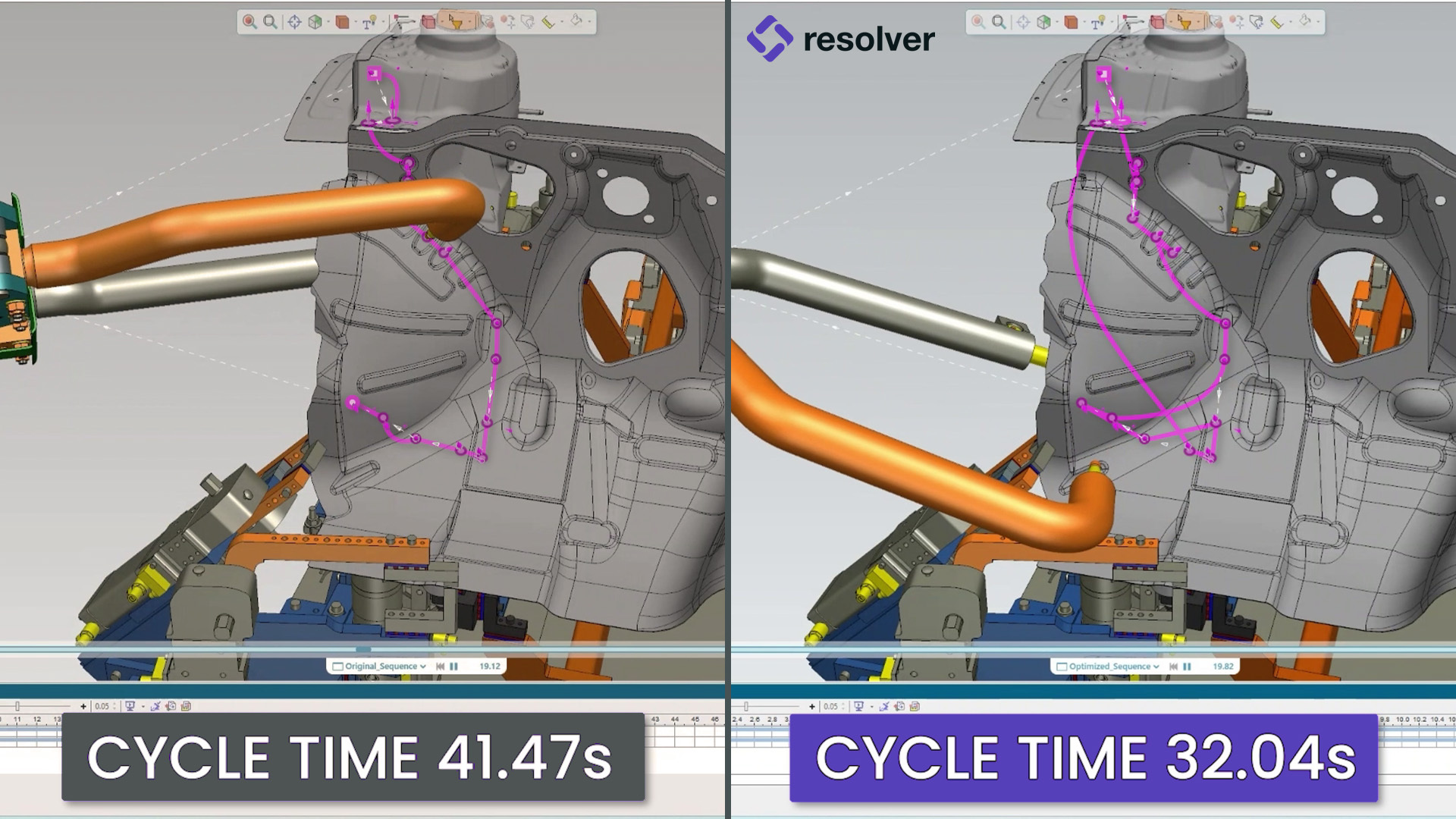

Realtime RoboticsのResolverは、ロボットワークセルの立上げにおけるあらゆるマニュアル作業を自動化することができます。今年前半の公式リリース以来、Resolverはサイクルタイム短縮とロボットセル立上げコストの削減に貢献してきました。しかしResolverの最も大きな貢献は、より複雑な課題を解決することにより工程設計そのものをポジティブに改善できることにあります。つまり、新しいロボットセルの立上げや新機種対応のためのアップデート、製品バリエーション対応など、様々なユースケースに適用できることです。Resolverを活用することで、製造プロセス全体におけるコストと効率の改善をご期待いただけます。

初公開されるResolver機能アップデート:

- FANUCロボットの拡張サポート:ResolverでのFANUCロボットのサポートがこれまで以上に強化され、アプローチおよびリトリートパラメータに開始距離/終了距離(SD/ED)を適用可能になりました。また、関節制限のあるロボット向けにも、新しい特性モデルと操作性の向上が実装されました。

- 動作制限の適用:ロボットのネイティブ制御の関節補間と外部関節補間の両方に動作制限を適用可能となりました。これまではネイティブ関節補間と外部関節補間の両方に動作制限が自動的に適用されていましたが、ツールではなくロボットのみに動作制限を適用できるようになり、手作業による修正作業が大幅に軽減されました。

- ユーザーインターフェイスの強化:エンドユーザーのログイン方法が改善され、GoogleおよびMicrosoftのシングルサインオン(SSO)をサポートされました。また、フォルダ構造にも見直しが適用され、スタディの管理がより簡単になりました。

- Visual Componentsの追加サポート:直線動作命令があらたにサポート追加され、作業中の開発環境を維持しつつResolverをさらに簡単に使用できるようになりました。

12月3日から6日まで東京ビッグサイトで開催されるiREX RTRブース(W4-61)で、体験型のロボットデモをぜひご覧ください。より詳しい情報は、こちらのリンクからもご確認いただけます。https://resolver.rtr.ai/blog/

Realtime Roboticsについて

Realtime Roboticsは、複数台の産業用ロボットセル向け非衝突動作計画、リアルタイム制御、最適化のソリューションを持つリーディングカンパニーです。ロボットの動作経路、インターロック、タスク配分やタスク順序を最適化し、製品設計やロボットセル立上げの劇的な効率化を実現します。

より詳しい情報はこちらからご覧ください。Website, YouTube, and follow us on X and LinkedIn.

Realtime Robotics to Debut Resolver for the Japanese Market at iREX 2025

Visit iREX Booth W4-61 to Experience the Interactive Resolver Demo and See the Latest Product Enhancements

BOSTON & TOKYO–iREX 2025—Realtime Robotics, the leader in automated collision-free motion planning, control, and optimization, today announced the official debut of Resolver in the Japanese market, the company’s cloud-based solution that dramatically accelerates an organization’s design, programming, and commissioning of robotic workcells, while decreasing its time-to-market.

In addition, the company premiered new features and enhancements for Resolver at iREX 2025, streamlining the end-user experience and expanding the number and type of robot models that Resolver supports. Realtime Robotics will be hosting a live, interactive demo of the solution and its integrations with Siemens Process Simulate and Visual Components in booth W4-61.

“There is a great deal of pressure on manufacturers to find a way to do more with less. They need to move faster, be more efficient, and more intelligent operationally in order to successfully compete on a global scale,” said Peter Howard, CEO of Realtime Robotics. “Our Resolver solution empowers manufacturers to quickly adapt and evolve their facilities and processes to keep pace with the speed of innovation, making changes and bringing products to market faster than ever before. We’re excited for the Japanese market to see what Resolver can do.”

Realtime Robotics’ Resolver automates the most time- and labor-intensive parts of robotic workcell design. Since its launch earlier this year, Resolver has helped manufacturers speed up cycle times while decreasing the cost of deployment. The true power of Resolver, however, lies in its ability to positively change the factory design experience by solving complex problems. It has been engineered to have the flexibility to be applied to a variety of use cases, including the initial design and ongoing redesign of new robotic workcells and manufacturing lines, as well as handling multiple variants. With Resolver, an organization’s overall costs are reduced while efficiency is improved.

The new features announced today for Resolver include:

- Expanded Support for FANUC Robots – Support for FANUC robots has been enhanced in Resolver, including the ability to use start distance/end distance (SD/ED) for approach and retreat parameters. A new characterization model and improved usability for robots with joint limits has been added as well.

- Applying Working Limits – Resolver now gives users the option of applying working limits to both native robot joints and external joints. Previously, the solution would automatically apply the working limits to both native and external joints; now, the user experience is improved by enabling working limits to be applied to just the robot – not the tool at the end of the robot – reducing manual touch ups.

- Enhanced User Interface – Resolver has improved the log in experience for end users, and now supports single-sign-on (SSO) options from Google and Microsoft. There is also an improved folder structure, making it easier to organize studies.

- Additional Visual Components Support – Resolver has added support for Linear Statement types in Visual Components, making it even easier to use Resolver without having to leave the development environment you’re working in.

To learn more and see the interactive Resolver demo, please visit iREX booth W4-61 throughout the event, which is taking place from December 3-6, 2025 in Tokyo.

For more information on these and other new additions to Resolver, please click here: https://resolver.rtr.ai/blog/.

About Realtime Robotics

Realtime Robotics is the leader in automated collision-free motion planning, control, and optimization for industrial robots. The company’s revolutionary technology dramatically accelerates the design and deployment of robotic workcells by solving for cycle-time optimized motions, interlocks, multi-robot coordination, real-time object detection and reaction, and robot task allocation. For more information, please visit our website, see our technology in action here, and follow us on X and LinkedIn.

Contacts

For More Information

Jeff Drew

Public Relations, Realtime Robotics

P: +1.617.233.5109

E: jeffreydrew@rtr.ai