Upload your workcell data directly from your simulation tool into Resolver’s cloud platform.

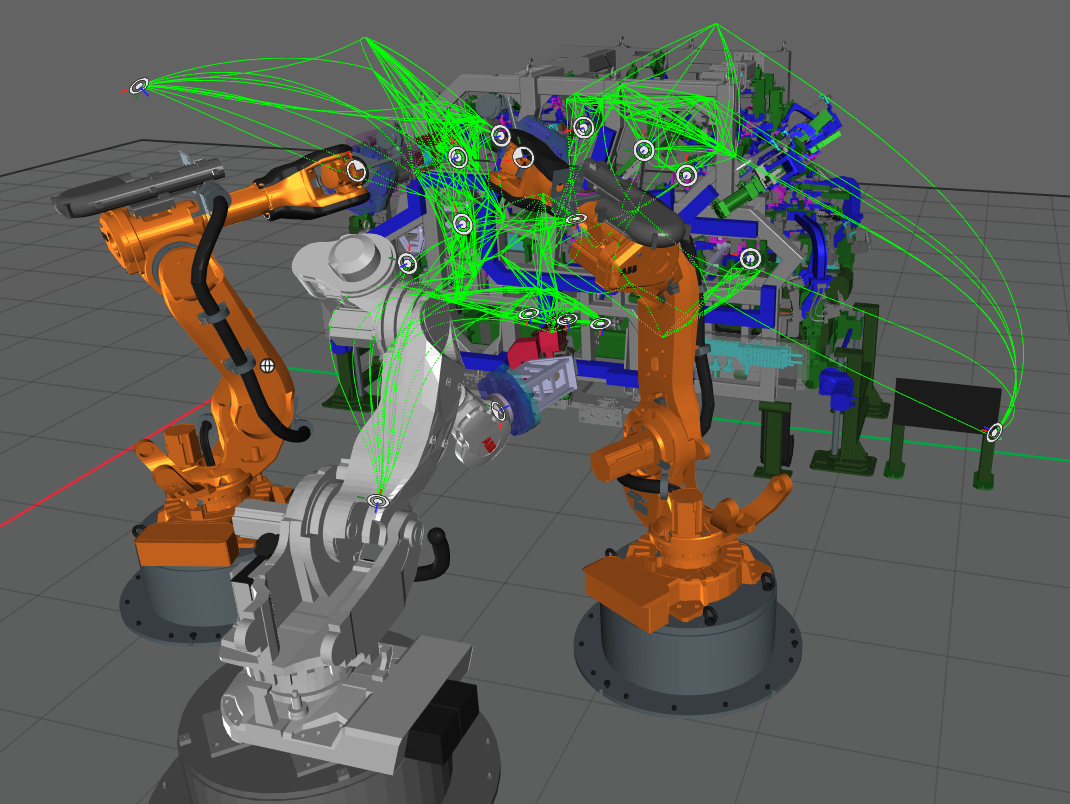

Spin up a project specific server and execute, letting it generate motion paths, interlocks, and task allocation—automatically.

Let Resolver run its industrial AI to solve problems too complex for humans and too massive for brute force compute.

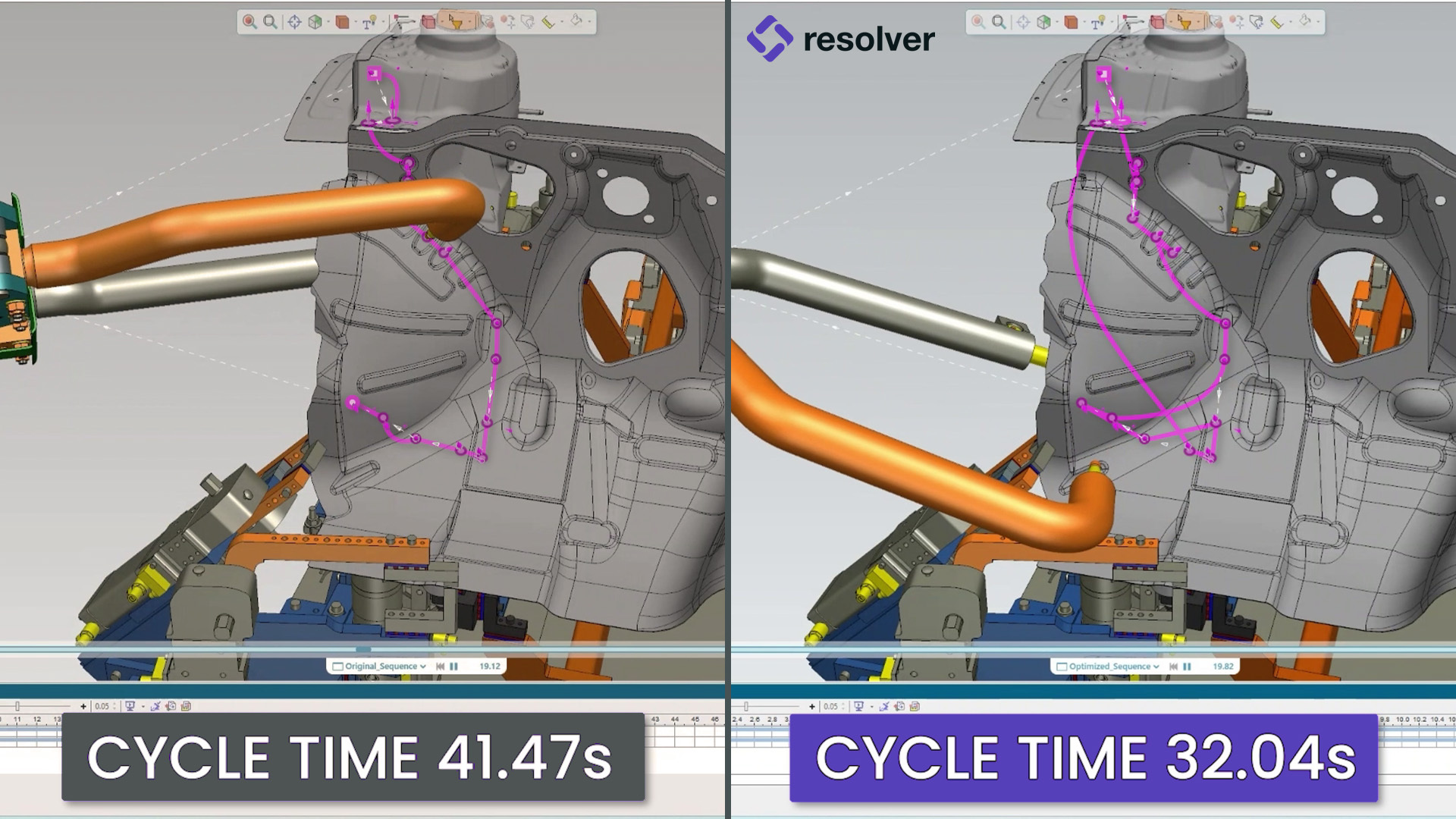

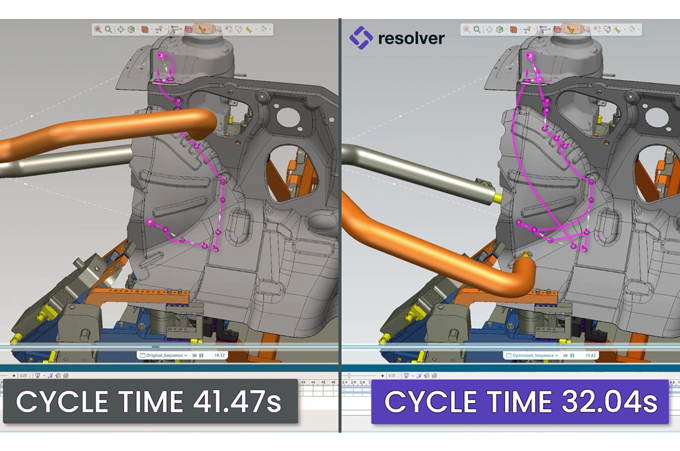

Discover fast results with cycle times that rival or exceed manual programming within minutes.

Continuously improve as Resolver extends the search to different approaches looking for the global minimum cycle time.

Export results seamlessly back into your simulation environment at any point —ready to validate and deploy.

Reach your goals and get alerted when a target cycle time is reached.

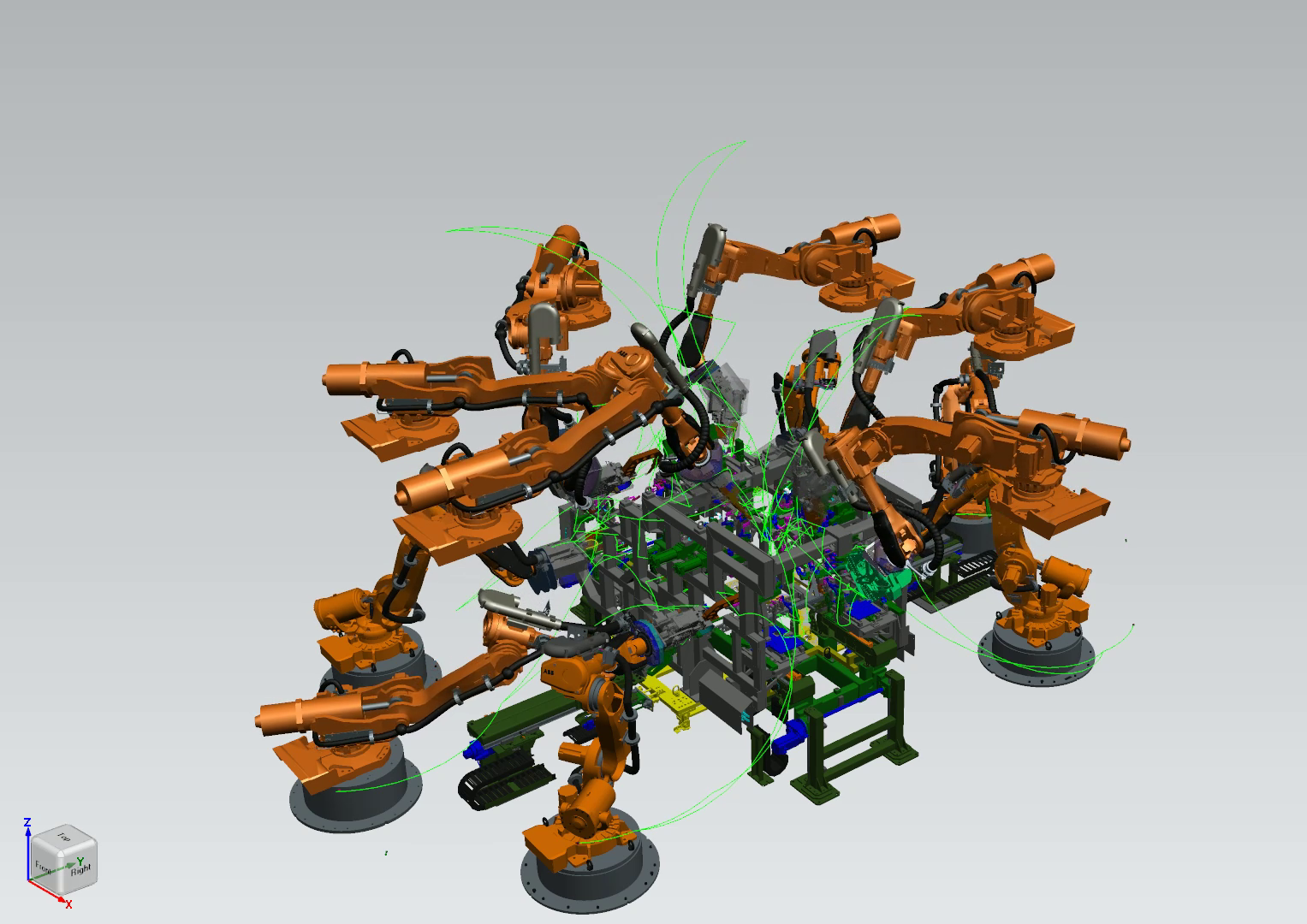

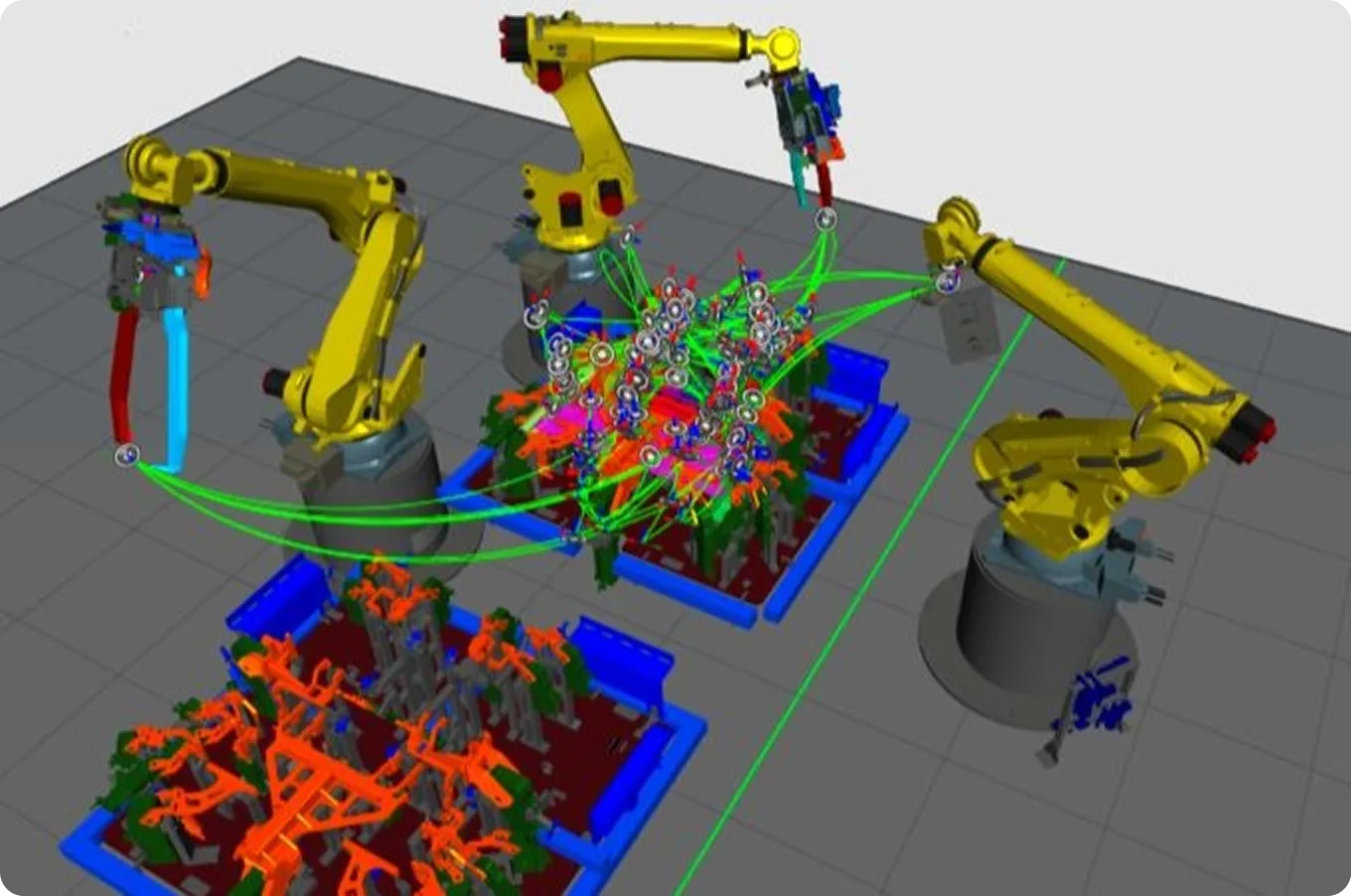

Optimize workcells, not just robots with paths and interlocks both taking 20+ neighboring robots into account.

Optimal path planning and interlock generation superior to anything our users have benchmarked us against, be it people or software.

Target Sequence optimization which can speed up a workcell by up to 20% on top of path planning.

Automatic task allocation per robot lets the proposal team skip manual target assignment and reduces cycle time by shifting tasks to less utilized robots.

Enormous compute capacity in the cloud dramatically speeds everything up compared to your laptop.

Unlimited parallel studies, enabled by the cloud, allow you to solve numerous what-if scenarios or the whole line overnight.

Access to the newest features with a variety of SIM tools, including older versions.

From Part CAD to paths in any cell in as little as 30min.

Submit low risk project proposals with trusted cycle times at minimal cost.

Evaluate required number of robots.

Validate mechanical design on demand 24/7 regardless of the availability of your simulation team.

Design optimal fixtures by building around the ideal paths, not the other way around, in a fraction of the time.

Optimize floor space use in a world where robot proximity adds zero extra effort, risk, or cost.

Start OLP with good paths and interlocks, dramatically reducing engineering time.

Get paths easily! Start with the minimum.

All you need to get started in your simulation tool are CAD objects, robots, and process points. Resolver will take care of the rest.

Optimize your cell design. Let it run.

Automatically generate cycle time-optimized motion paths, interlocks, reachability reports, robot task allocation, and more. Or try more advanced features coming out soon, like End of Arm Tool selection and automatic robot positioning

Even help design your fixtures. Work smarter, not harder.

Easily import results into your simulation tool and get accurate cycle times. If anything changes, easily reiterate with Resolver.

New Features Coming Soon!

Without Resolver |

With Resolver |

|---|---|

|

Average ~30h of work verifying mechanical and fixture design, ordering and allocating targets, planning paths, creating interlocks, and confirming safety for each robot for every iteration.

|

Trigger Resolver straight from your SIM tool, and depending on the task is done in minutes (validate design) or in hours (optimal paths), with a customer reported average reduction of ~50% in effort.

|

|

Recruit new robot programmers in a competitive market.

|

Leverage non-experts by giving them the capability to plan paths and validate designs themselves.

|

|

Have your team working overtime due to spikes in demand or negative surprises.

|

Use Resolver, with infinite scaling, as a multiplier for your existing team.

|

|

Define interlocks by hand—prone to errors, rework, and delays.

|

Define interlocks automatically alongside paths and task allocation with minimal extra work.

|

|

Ruin your day discovering your best path plans fall 5 seconds short.

|

Confirm cycle time already during proposal, operate as fast the robots can, and iterate the design rapidly in the worst case scenario.

|

|

Use a comfortable number of robots to make sure you hit the cycle time.

|

Test your optimistic robot setup overnight, and add another robot if it doesn’t work.

|

|

Come up with clever solutions to keep robots far enough apart to remove collision risk.

|

Create tight workcells, minimizing wasted footprint as robot proximity adds zero work or collision risk.

|

Supercharge digital twins and enable never before seen flexibility in a production environment.

Let your engineers test against an existing production line as early as design for manufacturing.

Jigless welding station updates without opening a simulation tool.

Rebalance the line with every change order.

Add a new variant to a production line in as little as a day.

End of Arm Tooling and robot selection based on optimal cycle times and financial variables.