Makes Robots Do Real Work, Real Fast, in the Real World

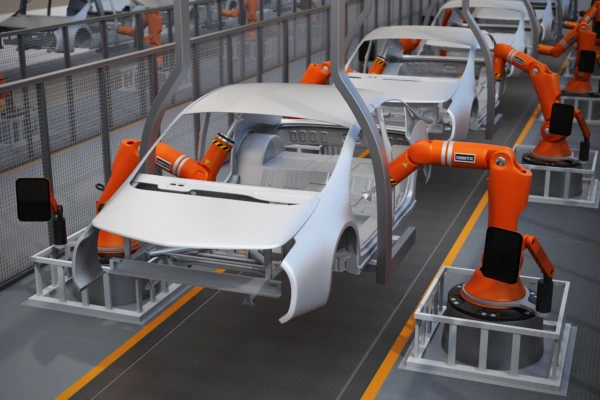

AUTOMATE – Chicago – (Apr. 10th, 2019) – Realtime Robotics, Inc. announced today the immediate availability of its collision-free motion planning solutions that make it possible for all robots to navigate dynamic environments smoothly, quickly and intuitively. Its RapidPlan and RapidSense solutions harness cutting-edge computer processing and software to enable industrial and collaborative robots to operate safely and collaboratively with people and other robots within workcells. The company will showcase the solutions as part of the Automate Launch Pad Startup Competition, held on Wed., Apr. 10 at 3 pm CT and in the company’s booth, 9649, at McCormick Place.

Today, robots are programmed to move from Point A to Point B along a single, defined path in order to complete a task. When something unexpected happens, such as an object is presented out of alignment, the path is interrupted, or an obstacle interferes with the programmed trajectory, the robot stops working and cannot resume until a person comes to resolve the issue. The loss of production time due to the event itself and the recovery time required to bring the workcell back online is costly.

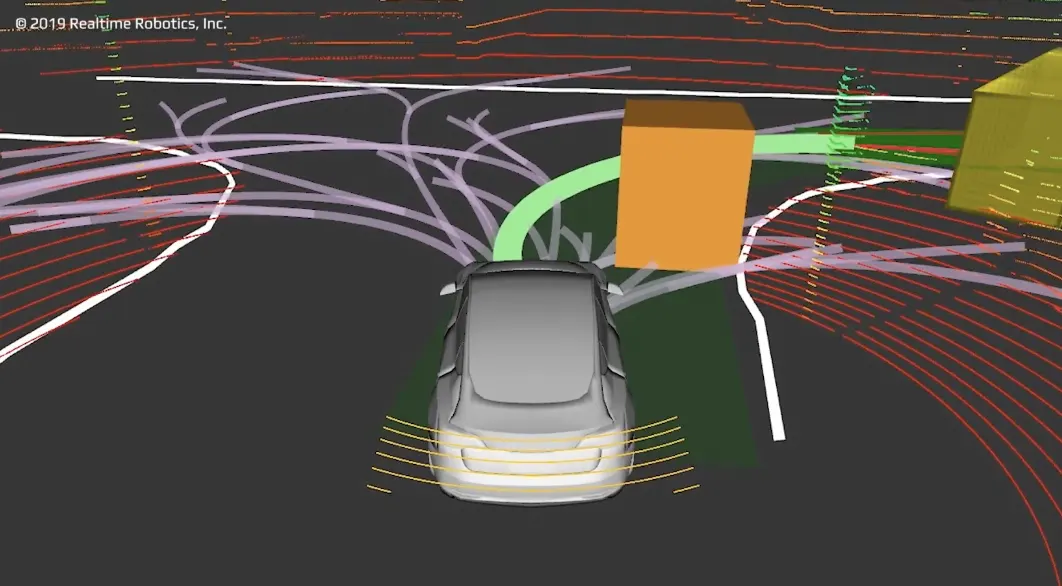

With the release of RapidPlan and RapidSense, Realtime Robotics eliminates this constraint by giving robots the ability to recognize and respond to changing environments. The result: manufacturers automate more tasks, more efficiently.

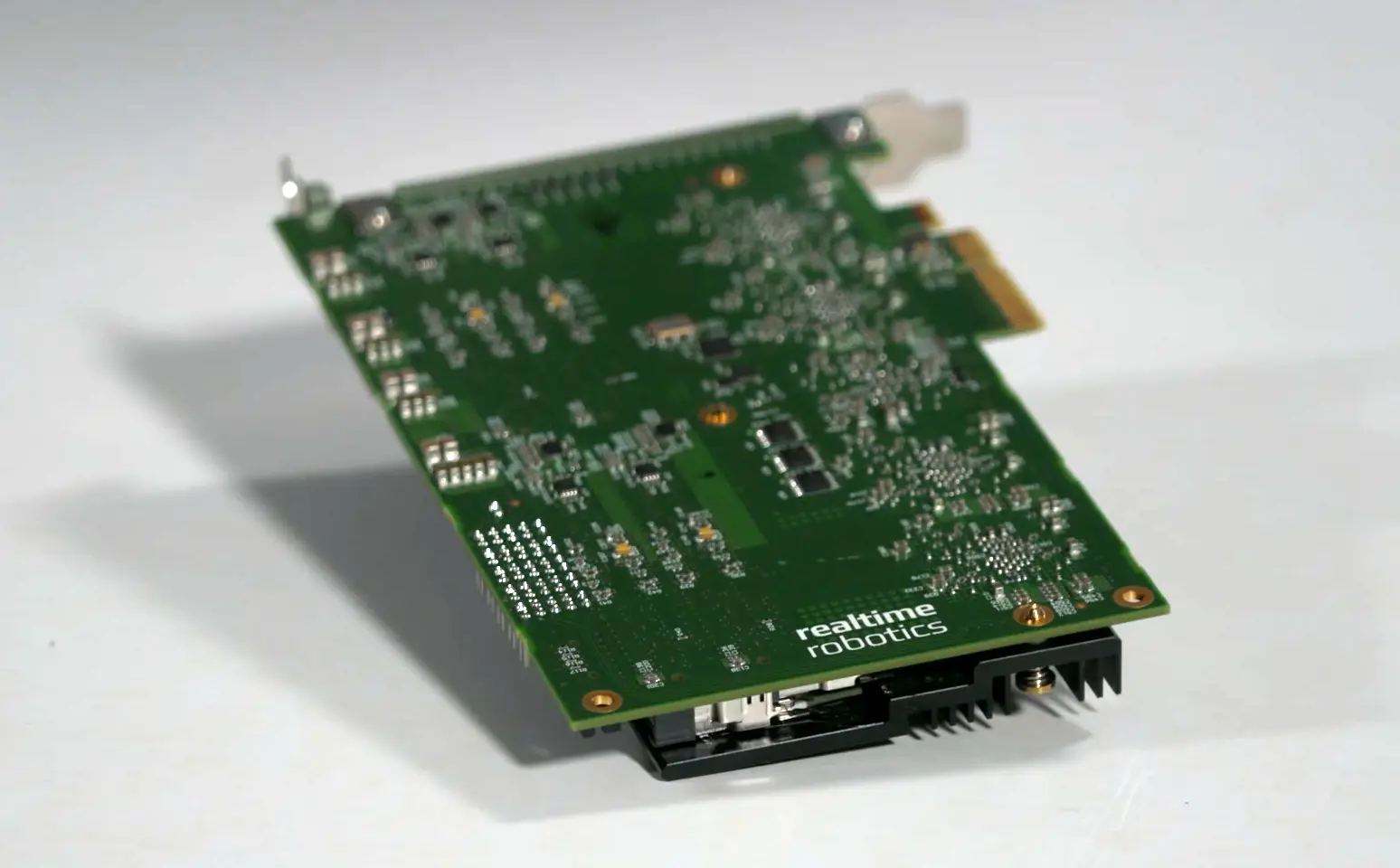

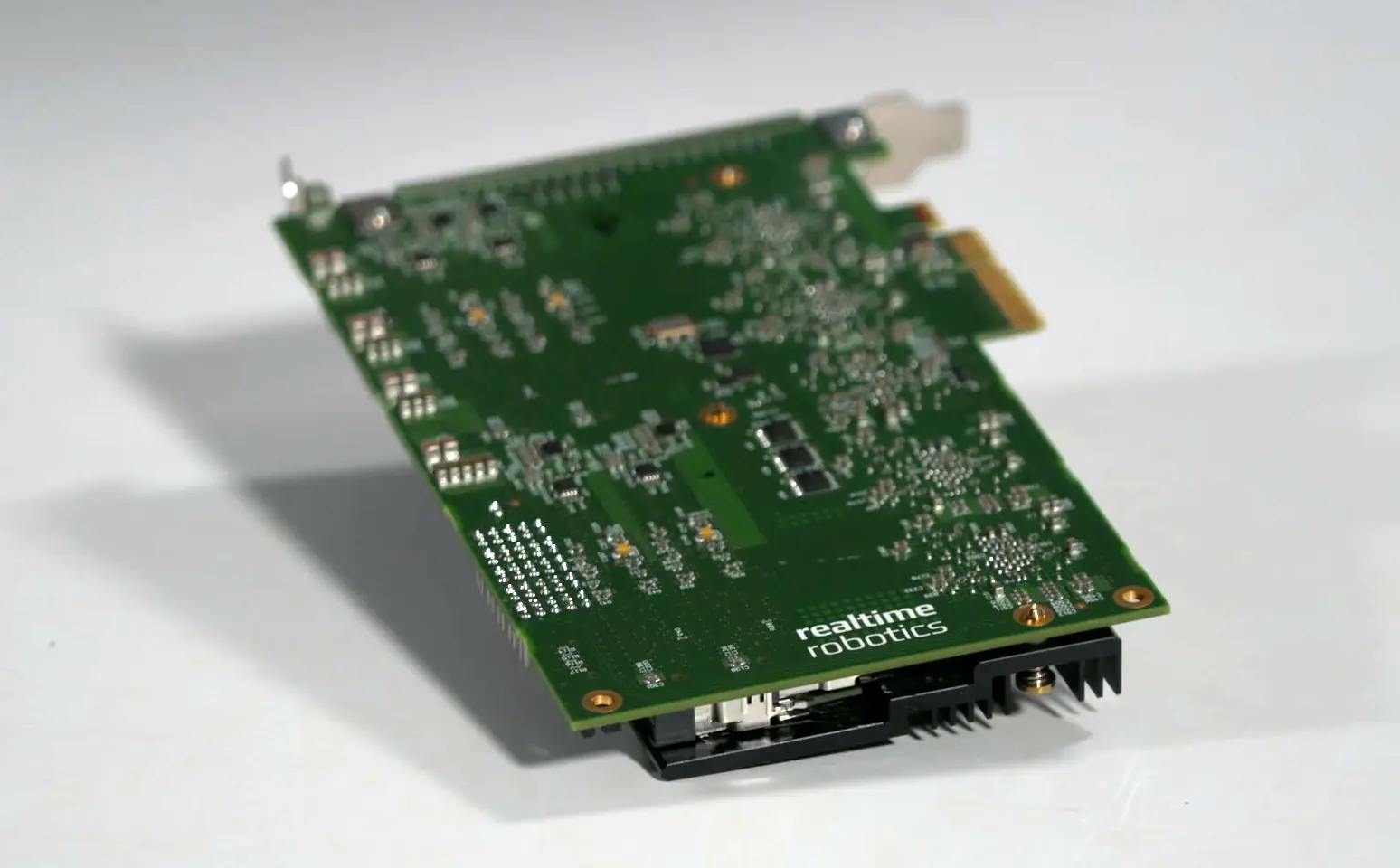

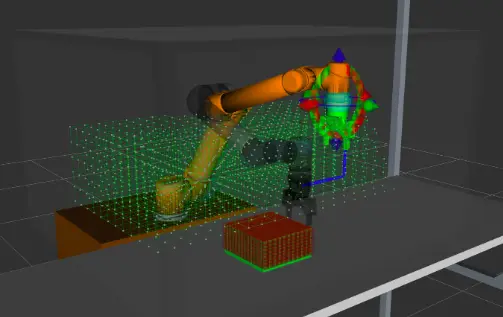

RapidPlan combines a hardware motion planning accelerator (MPA) with a software-based roadmap generation toolkit and is shipping now. It is robot-arm and sensor agnostic and can be integrated into new and existing workcells to drastically improve the safety and performance of both industrial and collaborative robots.

With RapidPlan’s unique combination of hardware and software, automation engineers in manufacturing and distribution operations gain unprecedented flexibility to create workcells for robots that reflect the realities of the environments in which they work. Using a highly intuitive interface, users can load as many as 20 million motions into the MPA. Once stored, RapidPlan can evaluate up to 800,000 motions at 30 frames-per-second in order to ensure that a robot continues to work regardless of interruption.

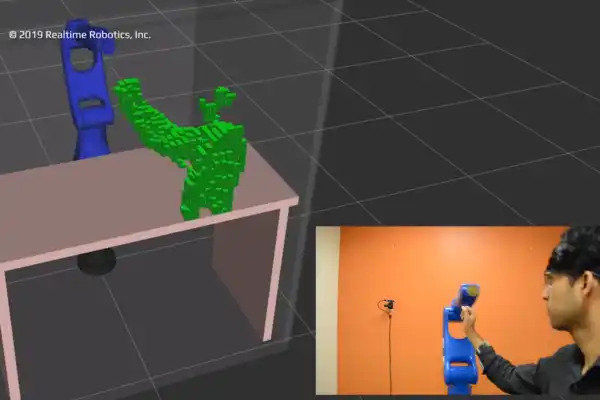

The company also announced the beta release of RapidSense, an advanced solution that enables robots to “see” everything within a workcell. The solution’s Calibration tool is a user-friendly interface that can autonomously calibrate as many as 10 depth-sensing cameras, vastly reducing setup and the reconfiguration time required when deploying vision systems. Once running, RapidSense sends data gathered with the cameras seamlessly to RapidPlan, making it possible for robots to dynamically replan to avoid a person, another robot, or an object that moves into the workspace.

Together, RapidPlan and RapidSense allow people and multiple robots to work collaboratively and cooperatively within the same workcell, without the need for expensive safety systems or time-consuming programming efforts.

“Automation professionals know that more automation is the key to increasing productivity and lowering costs; they also know that today’s robots are limited in terms of speed and safety… Our collision-free motion planning solutions allow robots to perform safely in dynamic, unstructured, and collaborative workspaces, while instantaneously reacting to changes as they occur.”

— Peter Howard, CEO, Realtime Robotics

About Realtime Robotics

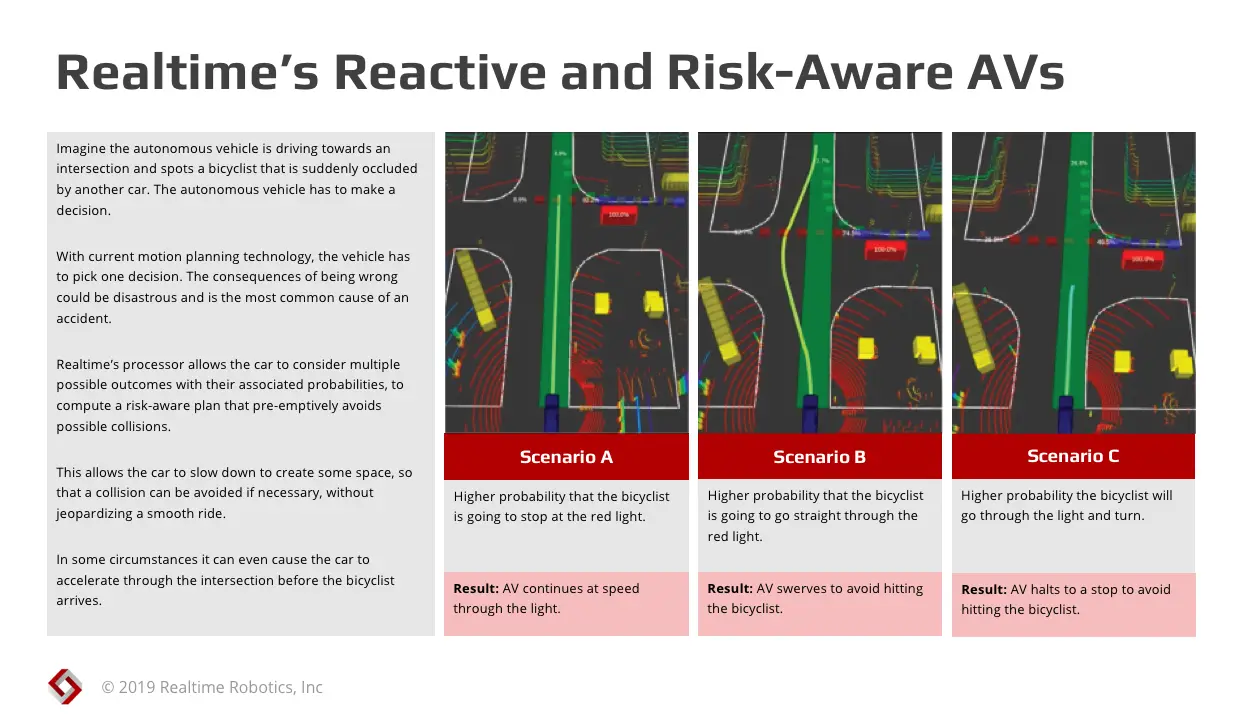

Realtime Robotics, Inc.’s responsive motion planning eliminates a huge challenge on the evolutionary path for robots and autonomous vehicles: the constraining trade-off between speed and safety. Its innovative products, RapidPlan and RapidSense, harness next-generation computer processors and software that make it possible for robots and autonomous vehicles to evaluate alternative scenarios and choose the optimal path to avoid collisions – all within milliseconds.

The company was founded in 2016, by Duke University professors Dan Sorin, George Konidaris, and top researchers Sean Murray and Will Floyd-Jones, based on groundbreaking DARPA-funded research in motion planning. Based in Boston, the company’s early investors include Sparx Group Co., Ltd., Toyota AI, and Scrum Ventures. More information about Realtime Robotics, its technology, and the business benefits it offers can be found on our website.