The leader in automated

collision-free motion planning,

control, and optimization.

Achieve cycle time faster

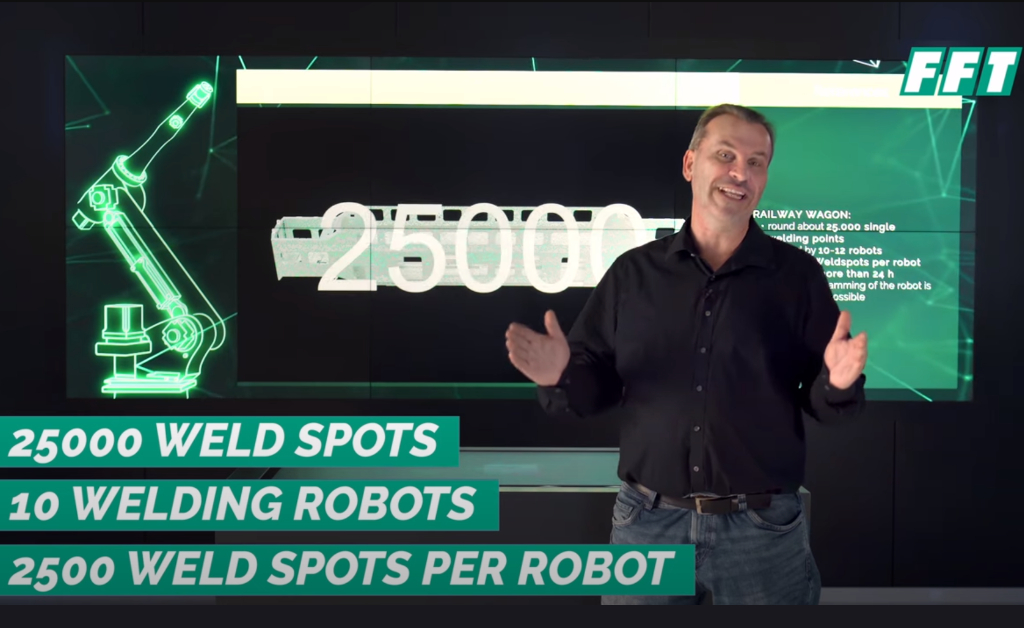

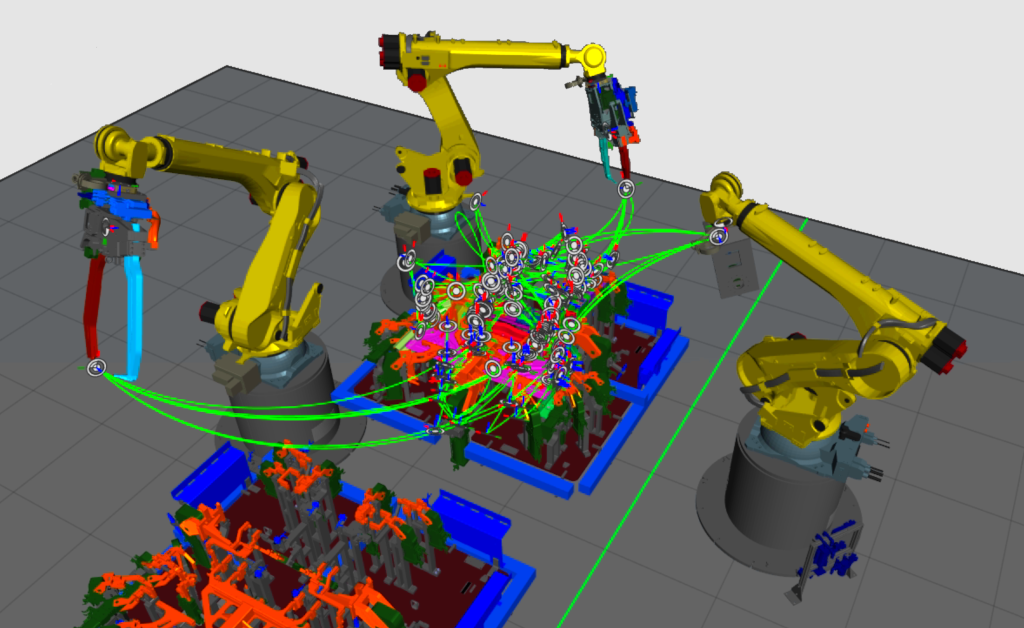

Realtime Robotics’ innovative technology generates and runs robots through optimized motion plans and interlocks to achieve the shortest possible cycle time in multi-robot cells. Our automated collision-free motion planning software and expertise enables you to:

- Finish projects faster by drastically reducing programming time

- Reduce expertise required to design and deploy robotic cells

- Hit your target cycle time on even the most challenging cells

Realtime’s real impact.

Our proprietary software and industrial automation expertise is the difference maker that can take your projects and performance to new heights.

5-20%

Reduction in cycle time for a major auto manufacturer

10-30%

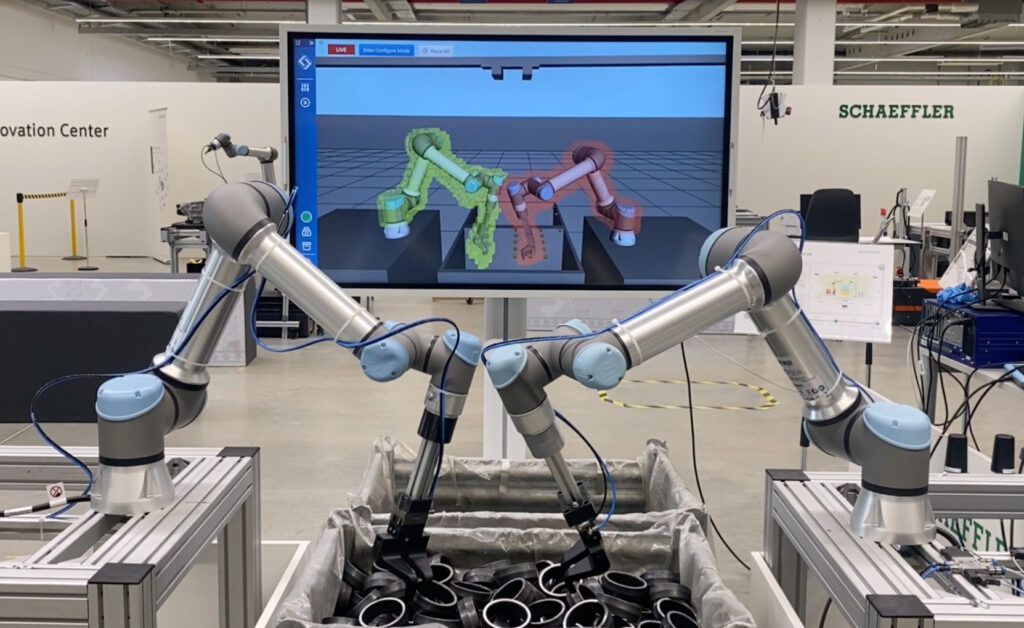

Increase in throughput for Schaeffler

70-80%

Reduction in programming time for Valiant TMS

Realtime’s real impact

Our proprietary software is the game-changer that can take your robots to greater efficiency.

Optimization: your cycle time shortcut

Realtime’s Optimization-as-a-Service uses a combination of proprietary optimization software and industrial automation expertise to help you reach your cell’s target cycle time in days or weeks, not months.

And with zero impact on existing processes.

Innovative solutions

Supercharge your picking, palletizing, and more.

Our software generates collision-free motion paths during runtime. Enable high throughputs and pick-rates for multiple robots while quickly reacting to changes in the market and supply chain.

We integrate with virtually every robot.

Increase your automation intelligence.

Decrease wasted time.

The easier programming is, the more time you’ll save. The more projects you’ll complete. And the more complex applications you can tackle. Learn how we can reduce downtime, increase efficiency and improve overall workcell performance.

Contact

Get in touch

Increase your automation intelligence. Decrease wasted time. Get in touch.

Fill out the form or call:

+1.617.302.6330.